Hello

I tried to search about the topic "Auto Height Control" and for my surprise found no posts about actually repairing the inoperative system. Please inform if You are aware of one, I'm interested in more information.

I have 1978 New Yorker Brougham with the mentioned system. I have narrowed the problems to control valve and the vacuum operated compressor. I have the 1978 FSM, but it has very little information of the system. Of course in the event of compressor failure, everything must be replaced as a unit...

By the way, I found the control valve in the rear wheel well to be very obsolete and undocumented. Hard to find any information about it, but I believe I can find suitable replacement for that.

The compressor kind of works - Turns slowly when vacuum is applied and makes erratic pressure sometimes. May achieve 10 psi of 150 psi rated. I disassembled the compressor and found 2 o-rings, which were dried. There were also 2 felt o-rings, which seem to disintegrate if touched. I may be able to find imperial o-rings that fit - information on exact dimensions will be appreciated. Could anyone tell more about the felt ones and the lubrication? Lubricant has dried decades ago but what I can tell, there should be some. The outlet check valve is hardened and should be replaced with a rubber ball of same sort.

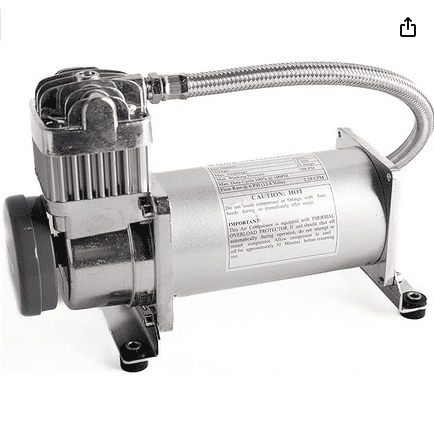

I'm also interested if someone has made entirely new compressor arrangement. For example 12V compressor with pressure switch stuffed into original location. That could be the backup plan if the original compressor turns out to be too difficult to repair.

Thanks for Your help in advance!

I tried to search about the topic "Auto Height Control" and for my surprise found no posts about actually repairing the inoperative system. Please inform if You are aware of one, I'm interested in more information.

I have 1978 New Yorker Brougham with the mentioned system. I have narrowed the problems to control valve and the vacuum operated compressor. I have the 1978 FSM, but it has very little information of the system. Of course in the event of compressor failure, everything must be replaced as a unit...

By the way, I found the control valve in the rear wheel well to be very obsolete and undocumented. Hard to find any information about it, but I believe I can find suitable replacement for that.

The compressor kind of works - Turns slowly when vacuum is applied and makes erratic pressure sometimes. May achieve 10 psi of 150 psi rated. I disassembled the compressor and found 2 o-rings, which were dried. There were also 2 felt o-rings, which seem to disintegrate if touched. I may be able to find imperial o-rings that fit - information on exact dimensions will be appreciated. Could anyone tell more about the felt ones and the lubrication? Lubricant has dried decades ago but what I can tell, there should be some. The outlet check valve is hardened and should be replaced with a rubber ball of same sort.

I'm also interested if someone has made entirely new compressor arrangement. For example 12V compressor with pressure switch stuffed into original location. That could be the backup plan if the original compressor turns out to be too difficult to repair.

Thanks for Your help in advance!

Last edited: