Forgive me if I’m wrong, but I don’t think I’ve seen anyone else do this job here on the forums before! I am sure most of you are familiar with me and my build by now, but if not - here’s a little background. Early 2020, I was 18 about to be 19 and bought my very first old car… a ‘68 New Yorker that’d been abandoned for 40 years. I’ve been working on restoring it ever since. All the work that’s been done to it has been done by me (except for big things like the engine / trans rebuild etc…) and the help of my great friend and mentor!!

We are close to getting this baby running once more for the first time since 1980! The trunk was pretty bad, the metal was eaten up by rust and there were holes that needed rid of.

We figured it’s best to do this repair work first before we even try to get this baby running due to having to drop the gas tank and all that fun stuff… So we did just that. Dropped the gas tank out which was by now completely dry. It actually had a drill hole where Tom Merkel, the previous owner drilled it out to drain the gasoline. Long story short - this guy was a little nuts… he had about 1,800 cars rotting in the Cuyama desert of CA. The state was not happy about this, due to environmental hazards or something like that. They made him drain the fluids of each car or else they were to be confiscated and crushed / scrapped. He did JUST that… which also explains why a lot of the things we’ve found on the car were remarkably clean like in the engine compartment and whatnot. Anyways back to the story.

My mentor has been building Kustoms and Hot Rods most of his life. He’s been a big Mopar fan and has built mostly Mopars! However they’ve all been pre 1960s Mopars. This is the first C Body he’s had a hand in building, and this is MY first car in general! So we had a bit of learning to do when it came to learning about the structure and frame work of the car. Initially I thought “Oh cool, I can just outline where I’ll cut with soapstone and do it all real easy!”

Well I was wrong! Since we are dealing with a unibody, a lot of the cutting had to be done underneath the car first. It was really hard for me since I’ve never used powered cutting wheels in my life. Basically I was cutting around all the sub frame work and supports that give the trunk strength, as well as cutting around where the leaf springs mount etc… It was a bit of a challenge, but in a few days time I got it done!

Now you can see INTO the frame and see the supports that connect to both sides and give the trunk the support it needs. I ground all those spot welds and popped off the remaining floor panels off the frame to expose the bare skeleton of the car.

Next step is to treat and kill the rust with acid, and grind down some of my jagged cuts to have a really smooth work area! Also just to use a flap wheel and clean up all the surface rust and make sure it’s all completely gone. After that, we will take the new trunk pan and set it where we need it to be. From there I’ll go underneath the car, stencil it out and mark where we should drill holes to redo the spot welds and hold that new pan in nice and tight! Slowly but surely this baby is coming along. Once everything is in place, I can repaint the trunk area and have it upholstered! Underneath, I can shoot on some rubberized undercoating and install the new gas tank and sending unit.

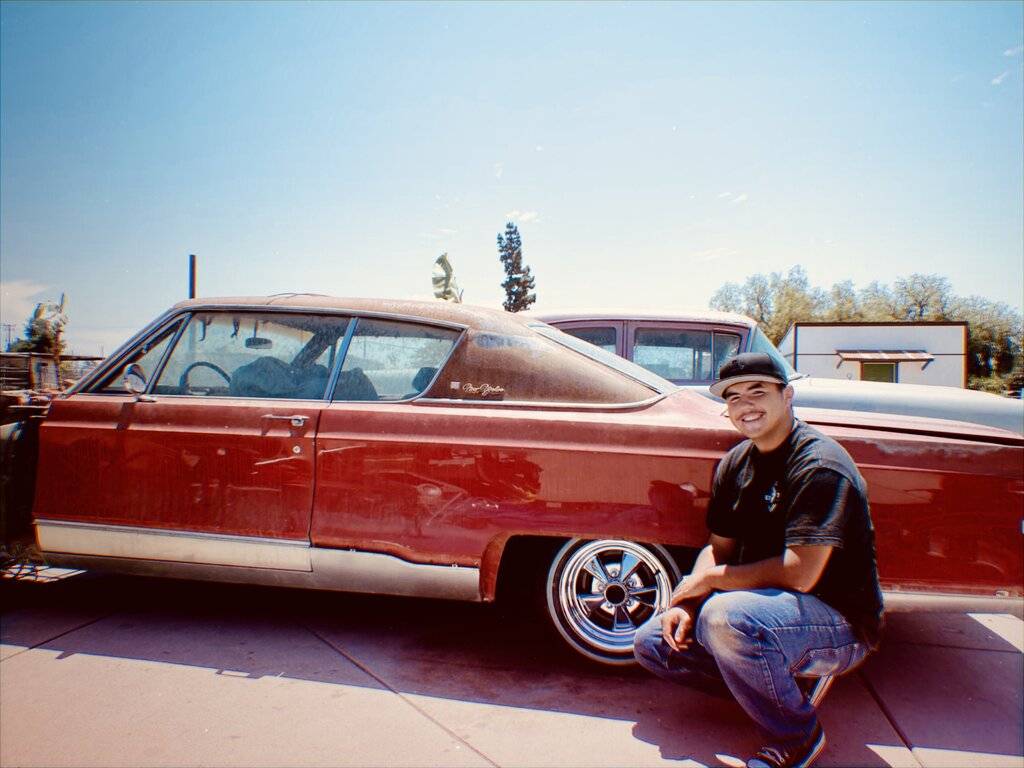

From there, we can move to the firewall for some patch work, as well as priming, blocking and painting it! At the same time we’ll remove the windshield front and back and do some metal work. I’ll pull the dash frame and install all the pieces I’ve put together for a “new” dashboard. Shannon at Redline Gauge Works is currently restoring my cluster to brand new! It will be amazing to see everything in place once again. Here’s a photo of me and my New Yorker only a few weeks ago. Here’s to many more memories and learning experiences!!

We are close to getting this baby running once more for the first time since 1980! The trunk was pretty bad, the metal was eaten up by rust and there were holes that needed rid of.

We figured it’s best to do this repair work first before we even try to get this baby running due to having to drop the gas tank and all that fun stuff… So we did just that. Dropped the gas tank out which was by now completely dry. It actually had a drill hole where Tom Merkel, the previous owner drilled it out to drain the gasoline. Long story short - this guy was a little nuts… he had about 1,800 cars rotting in the Cuyama desert of CA. The state was not happy about this, due to environmental hazards or something like that. They made him drain the fluids of each car or else they were to be confiscated and crushed / scrapped. He did JUST that… which also explains why a lot of the things we’ve found on the car were remarkably clean like in the engine compartment and whatnot. Anyways back to the story.

My mentor has been building Kustoms and Hot Rods most of his life. He’s been a big Mopar fan and has built mostly Mopars! However they’ve all been pre 1960s Mopars. This is the first C Body he’s had a hand in building, and this is MY first car in general! So we had a bit of learning to do when it came to learning about the structure and frame work of the car. Initially I thought “Oh cool, I can just outline where I’ll cut with soapstone and do it all real easy!”

Well I was wrong! Since we are dealing with a unibody, a lot of the cutting had to be done underneath the car first. It was really hard for me since I’ve never used powered cutting wheels in my life. Basically I was cutting around all the sub frame work and supports that give the trunk strength, as well as cutting around where the leaf springs mount etc… It was a bit of a challenge, but in a few days time I got it done!

Now you can see INTO the frame and see the supports that connect to both sides and give the trunk the support it needs. I ground all those spot welds and popped off the remaining floor panels off the frame to expose the bare skeleton of the car.

Next step is to treat and kill the rust with acid, and grind down some of my jagged cuts to have a really smooth work area! Also just to use a flap wheel and clean up all the surface rust and make sure it’s all completely gone. After that, we will take the new trunk pan and set it where we need it to be. From there I’ll go underneath the car, stencil it out and mark where we should drill holes to redo the spot welds and hold that new pan in nice and tight! Slowly but surely this baby is coming along. Once everything is in place, I can repaint the trunk area and have it upholstered! Underneath, I can shoot on some rubberized undercoating and install the new gas tank and sending unit.

From there, we can move to the firewall for some patch work, as well as priming, blocking and painting it! At the same time we’ll remove the windshield front and back and do some metal work. I’ll pull the dash frame and install all the pieces I’ve put together for a “new” dashboard. Shannon at Redline Gauge Works is currently restoring my cluster to brand new! It will be amazing to see everything in place once again. Here’s a photo of me and my New Yorker only a few weeks ago. Here’s to many more memories and learning experiences!!

Last edited: