slantsixdan

Member

- Joined

- Aug 10, 2011

- Messages

- 64

- Reaction score

- 82

Contact seller

Brand new OE turn signal switches are on my shelf.

These are newly made according to the final-revision Chrysler blueprint, by an original supplier to Chrysler. These are not the crude, poor-quality Chinese knockoffs available all over the place, and they are not the Shee-Mar parts that kindasorta fit and fail early and often; they are the real deal – they fit and work all the way correctly, and they have the correct snap/click switch operational feel.

Two types are available (click any pic for larger):

• With split-flat-spade Packard terminals for '62-'63 cars

(part № 2258 700)

• With "Twin-Lock" box-and-point terminals for '64-'69 cars

(part №s 2631 383, 2496 163, 2822 170, 2857 241)

Applications are A-bodies, B-bodies, and C-bodies, and (some) Imperials without tilt steering column.

A loose and sloppy, worn-out old switch is a pain (no click-snap into position, no self-cancelling, wondering if both your brake lights will work today…). Spend endless money-time-effort on repeatedly-failing poor-quality ones, spend a mountain of money on a new old stock switch…or buy one of these new-new-stock switches off me for $129.82 + $13.18 postage (for up to 3 switches) within the lower 48 states = $143.00, USD.

Shipping (from Michigan) by Priority Mail, within the US, usually takes about a week. Postage to other locations on request. Please send me a PM.

About that horn contact:

These switches have the solid-copper brush type of horn contact, rather than the roller wheel. This might make you squawk, and it's understandable why: a lot of the crummy-quality switches have a poorly-made version of the solid brush, and because that's a visible difference to the old-production OE switches, it came to be associated with the crummy ones, and people came to look out for the solid brush as an indicator (zing!) of a switch to avoid. Also, it's not common knowledge that when installing a switch with the solid brush, you apply appropriate lubricant to the contact ring on the back of the steering wheel so there won't be any noise made as the brush slides on the contact ring, so people would install them dry, and then when they heard noise from it, they'd decide that meant the solid brush contact is no good.

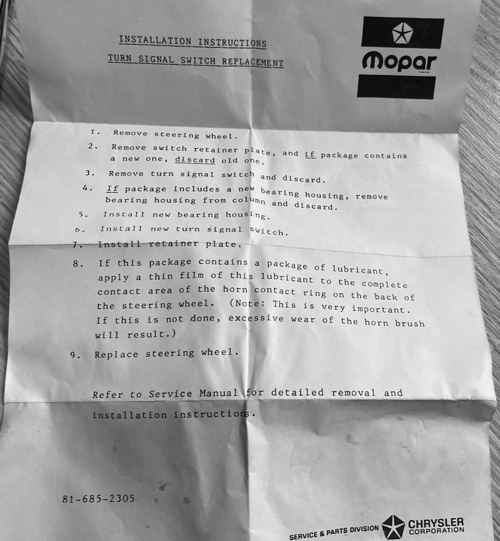

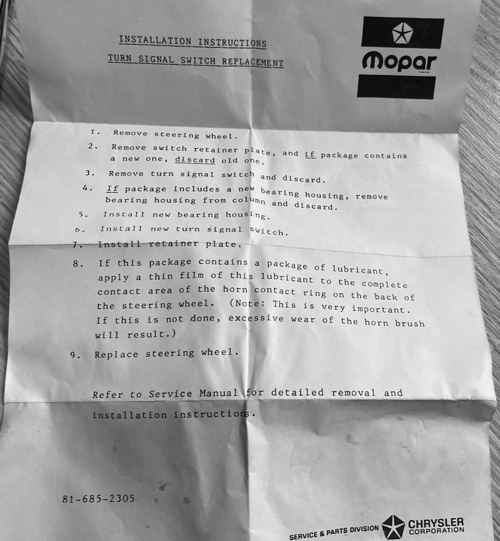

There's nothing wrong with the brush-type horn contact, if it's made well and installed properly. Chrysler themselves phased out the roller wheel and went to the solid brush in the early-mid '70s on all OE turn signal switches, and Mopar replacement switches came with a sheet advising the installer to apply a thin film of lube to the contact ring:

For awhile, the Mopar switches came with a little capsule of appropriate lube, a graphite grease. I don't have any such capsules, but graphite grease is easy to buy, or you can make some by mixing regular graphite powder into regular white lithium grease. Or dry graphite-film spray would do the job. Or heck, if I had none of the above and needed to install a switch in a hurry, I'd grab a regular № 2 pencil and apply it all over the contact ring, then assemble it and drive off. The need here is just for something slippery and conductive.

The Chrysler blueprint for these '62-'69 switches has provisions for either type of setup, roller wheel or solid brush, and the horn brush assembly in my switches is really nicely made: appropriate diameter slug of good copper, chamfered so it won't chatter; good, lively fully-enclosed spring, precise fit of the brush within its sleeve so it won't bind, etc.

And after all that, if you still have doubts about it, I guess there are two good answers:

• There are brushes and not roller wheels in your alternator, starter, blower motor, and wiper motor.

• These are still the best switches on the planet for this application.

These are newly made according to the final-revision Chrysler blueprint, by an original supplier to Chrysler. These are not the crude, poor-quality Chinese knockoffs available all over the place, and they are not the Shee-Mar parts that kindasorta fit and fail early and often; they are the real deal – they fit and work all the way correctly, and they have the correct snap/click switch operational feel.

Two types are available (click any pic for larger):

• With split-flat-spade Packard terminals for '62-'63 cars

(part № 2258 700)

• With "Twin-Lock" box-and-point terminals for '64-'69 cars

(part №s 2631 383, 2496 163, 2822 170, 2857 241)

Applications are A-bodies, B-bodies, and C-bodies, and (some) Imperials without tilt steering column.

A loose and sloppy, worn-out old switch is a pain (no click-snap into position, no self-cancelling, wondering if both your brake lights will work today…). Spend endless money-time-effort on repeatedly-failing poor-quality ones, spend a mountain of money on a new old stock switch…or buy one of these new-new-stock switches off me for $129.82 + $13.18 postage (for up to 3 switches) within the lower 48 states = $143.00, USD.

Shipping (from Michigan) by Priority Mail, within the US, usually takes about a week. Postage to other locations on request. Please send me a PM.

About that horn contact:

These switches have the solid-copper brush type of horn contact, rather than the roller wheel. This might make you squawk, and it's understandable why: a lot of the crummy-quality switches have a poorly-made version of the solid brush, and because that's a visible difference to the old-production OE switches, it came to be associated with the crummy ones, and people came to look out for the solid brush as an indicator (zing!) of a switch to avoid. Also, it's not common knowledge that when installing a switch with the solid brush, you apply appropriate lubricant to the contact ring on the back of the steering wheel so there won't be any noise made as the brush slides on the contact ring, so people would install them dry, and then when they heard noise from it, they'd decide that meant the solid brush contact is no good.

There's nothing wrong with the brush-type horn contact, if it's made well and installed properly. Chrysler themselves phased out the roller wheel and went to the solid brush in the early-mid '70s on all OE turn signal switches, and Mopar replacement switches came with a sheet advising the installer to apply a thin film of lube to the contact ring:

For awhile, the Mopar switches came with a little capsule of appropriate lube, a graphite grease. I don't have any such capsules, but graphite grease is easy to buy, or you can make some by mixing regular graphite powder into regular white lithium grease. Or dry graphite-film spray would do the job. Or heck, if I had none of the above and needed to install a switch in a hurry, I'd grab a regular № 2 pencil and apply it all over the contact ring, then assemble it and drive off. The need here is just for something slippery and conductive.

The Chrysler blueprint for these '62-'69 switches has provisions for either type of setup, roller wheel or solid brush, and the horn brush assembly in my switches is really nicely made: appropriate diameter slug of good copper, chamfered so it won't chatter; good, lively fully-enclosed spring, precise fit of the brush within its sleeve so it won't bind, etc.

And after all that, if you still have doubts about it, I guess there are two good answers:

• There are brushes and not roller wheels in your alternator, starter, blower motor, and wiper motor.

• These are still the best switches on the planet for this application.