bajajoaquin

Senior Member

I mentioned this in my ongoing Imperial thread, but didn't post up a question, because it's one of the things I've come across that's Imperial only, and not a general C-Body question. But here goes anyway....

It appears that the "Isolator" on the driver's side of my Imperial is bad. With the car on a lift, and resting on its suspension, if you grab the aft end of the driver's side torsion bar, you can wiggle it. You can also hear it rattling as you go down the road, as long as the suspension is unweighted.

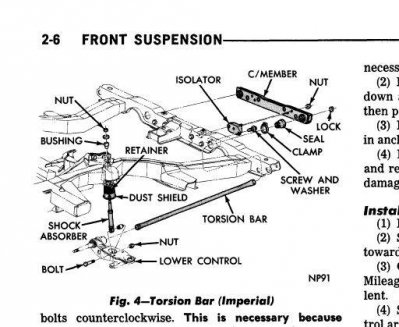

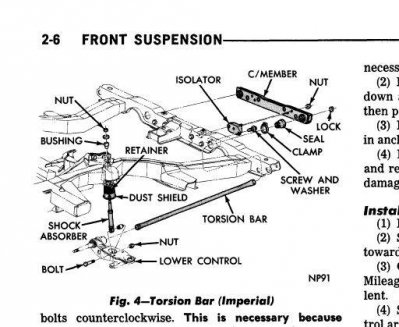

Looking at the FSM, the parts involved are the "Isolators."

According to the FSM, this can be removed from the car by unloading the torsion bars and removing/replacing them. They can "only be serviced as a unit." I have not yet gotten a wrench on them to find out if they're simply loose, but I expect they're just old and rotten. I'm saying "them" even though it's only the driver's side. I'm sure the other one will go next.

I've called or emailed several old and obsolete suspension part companies, and so far no joy. I've also put a post on the Imperial group.

Anyone here have any ideas or suggestions?

It appears that the "Isolator" on the driver's side of my Imperial is bad. With the car on a lift, and resting on its suspension, if you grab the aft end of the driver's side torsion bar, you can wiggle it. You can also hear it rattling as you go down the road, as long as the suspension is unweighted.

Looking at the FSM, the parts involved are the "Isolators."

According to the FSM, this can be removed from the car by unloading the torsion bars and removing/replacing them. They can "only be serviced as a unit." I have not yet gotten a wrench on them to find out if they're simply loose, but I expect they're just old and rotten. I'm saying "them" even though it's only the driver's side. I'm sure the other one will go next.

I've called or emailed several old and obsolete suspension part companies, and so far no joy. I've also put a post on the Imperial group.

Anyone here have any ideas or suggestions?