After the other crack checks are found to be O.K. have couple .000s shaved to make sure the headz are flat. And another couple .000s to have the same knowledge on both deck's and you're good to go for the rebuild. AH SHORT TAIL AND LEARNING EXPERIENCE ON TRYING TO CUT CORNERZ ON A REBUILD WHICH WAS NOT MY INTENT... In '06 I had ah guy that came highly recommended with 30 yearz experience rebuild a well seasoned '67 Imperial block(sorry Matt) and told him to shave ah couple .000s off the headz and straight edge the decks and if they were flat leave them alone and carry on with the rebuild and he did just that. Problem waz and I never knew that he never removed the head locating pins when he did the straight edge treatment so when he got to that point he just jumped the pinz and continued on. Completely missing a low spot in front of the front pin on the left bank and another low spot in the bridge between #3 and #5 so bad move on his part that built me an A$$ kickin' 440 POS that I got ah whole 13 hours on beyond ah half hour break in before It started blowin' white smoke. And yeah know what? After almost a year of bickering back and forth with this dude I ate the 5K+ cost of the rebuild and moved on. That's when I found Eric of Muscle Motors up in Lansing, Michigan and we became and are still good friendz. Fortunately I had a 2nd. '67 Imperial block(sorry X2 Matt) to do it right the 2nd. time AND FORTUNATELY AGAIN MOST PIECES TRANSFERRED OVER AFTER SOME LINE BORING AND AH FEW NEW BEARINGZ. Because that 1st. 440 when the head gasket blew, #5 filled up with antifreeze so fast that it took out that TRW flat top and put chunks of it and the ringz in between the piston and the wall on #5 and cracked the block before I could get it stopped. I'm done! Your call on what you do for a rebuild, Jer

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

906 heads

- Thread starter jake

- Start date

Wollfen

Old Man with a Hat

I'm not sure if anyone has mentioned it but when you get your heads done make sure you get hardened exhaust valve seats put in, just for piece of mind.

70bigblockdodge

Old Man with a Hat

Or just buy a set of aluminum heads.

The further the bickering goes on the big block advice thread the less I'm am impressed with aluminum heads, if I bought a set of those I think I would have to buy them through someone who knows what they are doing and have them set up properly before I get them and that eliminates the $1000 price so they are not a tit for tat swap. If your not shooting for at least 600 HP and stuffing it in a light shell just seems like a" look what I have and you don't type of feather ruffling"

Lots of great info. I don't need it now but in the future. Definite favorite save for later.

heyoldguy

Member

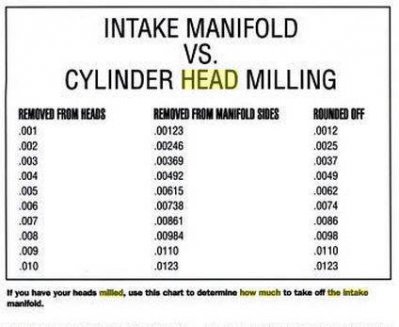

Put the $200 toward the 516 heads having the exhaust opened to 1.74 and brand new stainless one piece valves you will be way further ahead. For less than $100 like previously mentioned take a chance. BTW Brian I think it is .006 off the intake for every .010 off the surface.

On the big block wedge heads you would mill .0123" from the intake surface for every .010" off the combustion chamber side.

70bigblockdodge

Old Man with a Hat

I knew I should have looked it up before posting that, that is why I put "think" in there lol. I was half right.

I knew I should have looked it up before posting that, that is why I put "think" in there lol. I was half right.

I should have looked it up too. Finally did

Similar threads

- Replies

- 51

- Views

- 7K

- Replies

- 1

- Views

- 353

- Replies

- 5

- Views

- 1K

- Replies

- 0

- Views

- 545