Nice work Marty!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hobby Upholstery shop setup and projects

- Thread starter HWYCRZR

- Start date

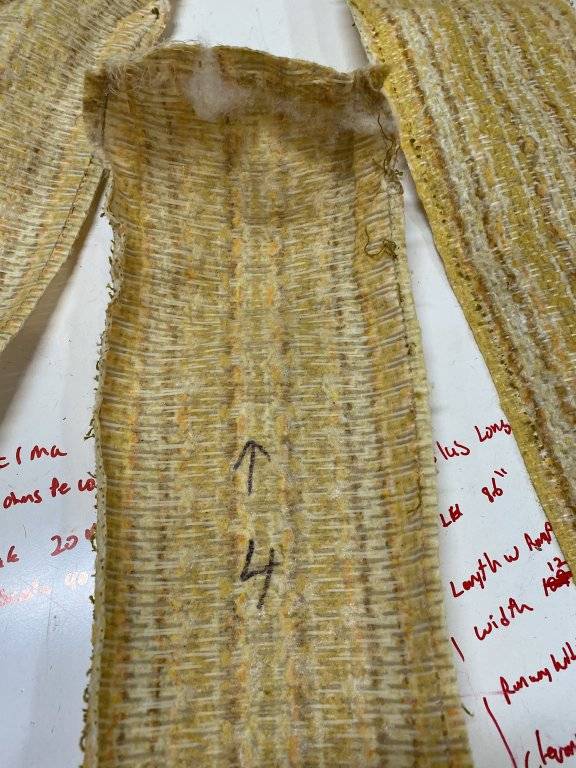

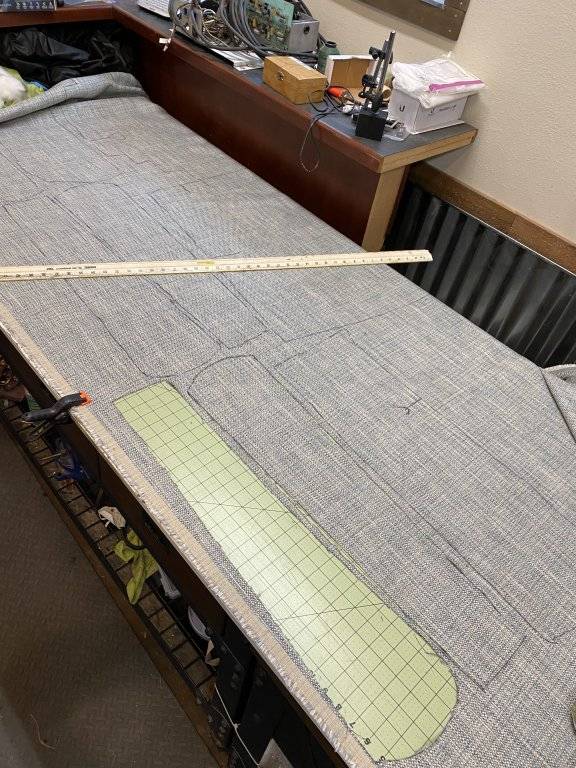

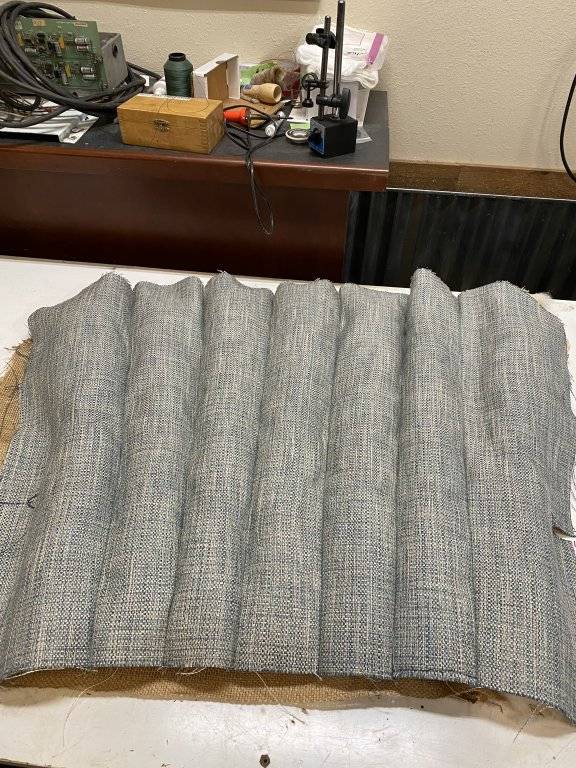

Here’s another project that I did a year or so ago. My wife found a chair she liked on Marketplace. It had the true ‘70’s vibe and smelled like it was the official smoking chair. So instead of leaving it there she gave them the $10 and brought it home. The fabric felt that if you were to sit on it, it would turn to dust. So she got it home and asked if I could fix it. I had never done the scalloped rolls, so figured I could reverse engineer them.

I had some challenges getting the rolls even, but in the end turned out ok.

Again I had a good pattern. I couldn’t find a before disassembly pic.

I had some challenges getting the rolls even, but in the end turned out ok.

Again I had a good pattern. I couldn’t find a before disassembly pic.

Now the rebuilding. (Winter 2020) I think after this project I got my new sewing machine. The trick with the rolls was to use a little bit of tack spray to help hold it in place, but not too much so that you can’t massage out the lumps.

You may see a theme here. If I have a pattern I can easily figure it out. I am starting to learn to take into account the previous stretching of the fabric and correct for it. Also mirror image is important from side to side. If one side is over stretched, you can usually use the opposite side flipped over to trace the shape.

I need a little more experience before I can just drape a piece of material over a frame and cut it out. I am starting to learn.

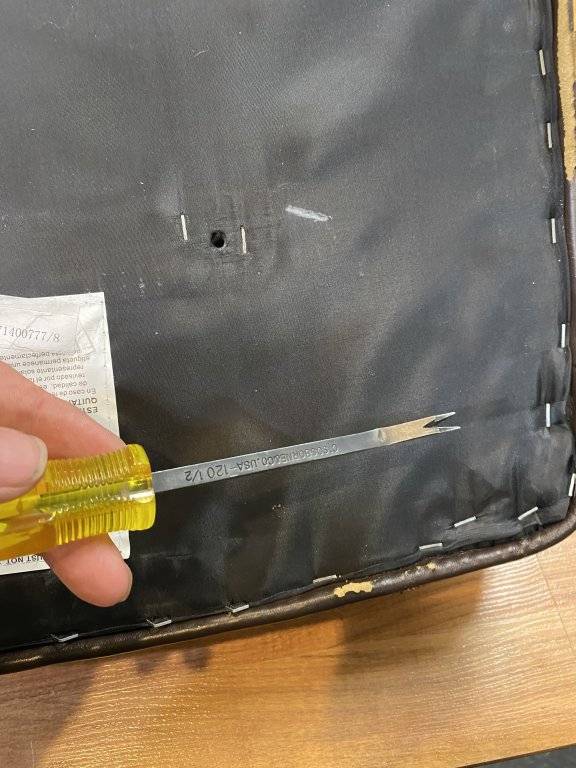

One last lesson. When removing staples with a sharp staple remover keep your other hand away from the points. You will slip and get snake bit.

I need a little more experience before I can just drape a piece of material over a frame and cut it out. I am starting to learn.

One last lesson. When removing staples with a sharp staple remover keep your other hand away from the points. You will slip and get snake bit.

Now that the upholstery job is complete I, I converted over to a regular work bench. Decided it was time to pull my Suzuki TC125 engine and transmission apart and refresh it.

Found another project ‘74 Suzuki TC125 Prospector

Will add more to that thread in a bit.

Found another project ‘74 Suzuki TC125 Prospector

Will add more to that thread in a bit.

65sporty

Old Man with a Hat

You have some skills

'66 Fury I

Active Member

I have great respect for those who work with fabrics. Metals, wood and rigid plastics are "dimensionally stable", while fabrics twist, stretch and distort so easily.

Your skill is amazing. Lindsay

Your skill is amazing. Lindsay

Similar threads

- Replies

- 20

- Views

- 2K

- Replies

- 3

- Views

- 394

- Replies

- 9

- Views

- 2K