Looks no different than what our '66 Newport 383 2bbl looked way back when. No issues with carb jetting, etc. Coloration is from fuel additives and is of no concern. Nobody messed with 2bbls back then, so everything should be fine.

As to the smell of the exhaust, before starting the warm engine, gently turn each of the idle mixture screws inward to very lightly seat them, then turn them back out 1.5 turns for the base setting. Then after starting the engine, check the hot base idle speed against the factory spec in "P". Then turn each screw outward .25 turn and see how the idle speed reacts, then put it back where it was. Same with the other idle mixture screw. From there, aim for the highest idle speed, then adjust the idle speed screw down, if needed. Now that things have been optimized, fine-tune that by turning IN the screw until a 20rpm drop happens, then back. Same with the other idle mixture screw.

After doing all of that, then increase the engine rpm for about 30 seconds or so, then gradually let it come back to idle. Then check the smell and see how intense it might be (hopefully minimized).

Way back when, I tried to use a vacuum gauge to do the idle mixrure settings, with mediocre results, to me. Never could get the vac readings at idle it seemed that I should. Ended up getting a quality dwell-tach and THEN things happened like I wanted them to. Much more accurate and repeatable.

The ign timing at idle should be at 12.5 degrees BTDC. Vac advance hose unplugged and plugged. Hooked to ported vacuum. According to the factory service manual, the centrifugal advance should not start until about 1000rpm or so, well above the hot base idle speed. I'm presuming it is NOT a California-sold Cleaner Air Package car.

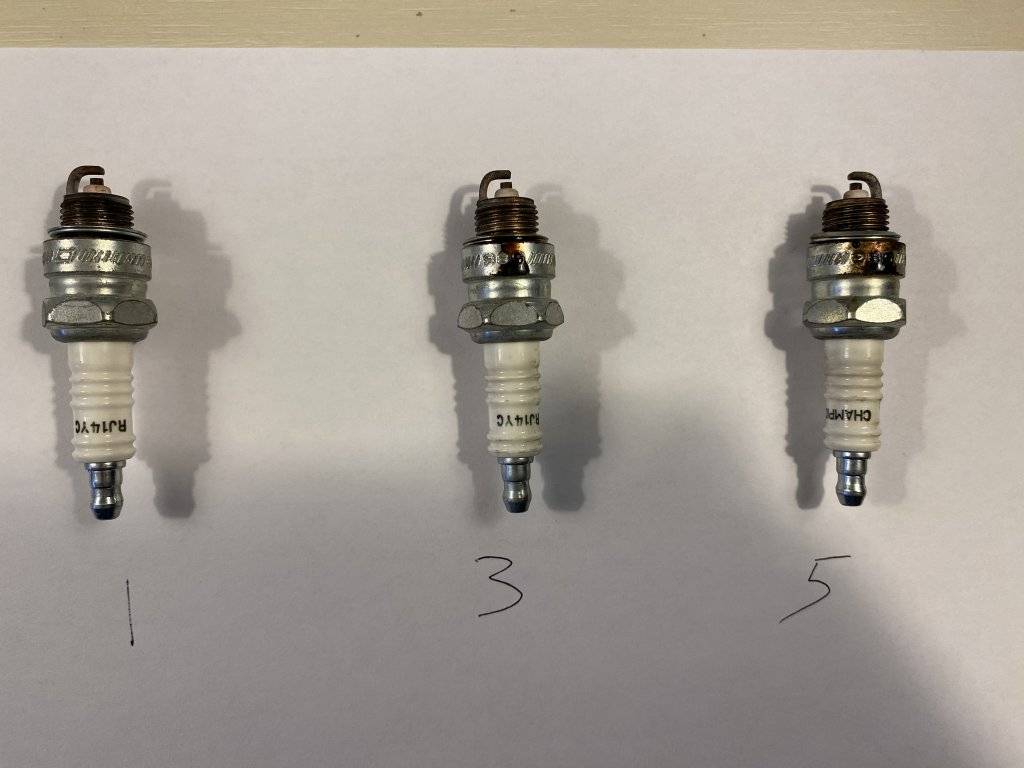

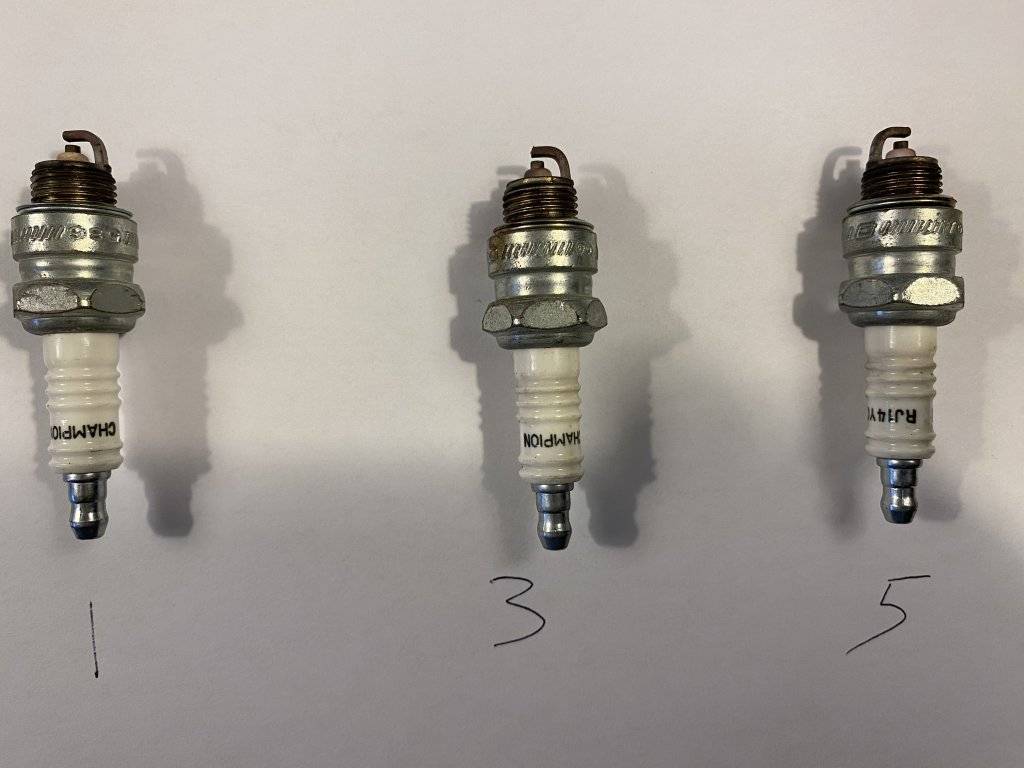

Oil in the outside of the plug hex is probably from a seeping valve cover gasket, like always. Many seeps will not hit the ground, so you don't know they are there until you might pull the plugs out to look at them. No problems.

IF the spark plugs are "loose", you'll know it. When putting them back in, screw them in with your fingers, or in a socket, finger-tight. Then go about 1/4 turn past that to compress the gasket. You're done. With a drop of engine oil (from the end of the dipstick works well) on the threads, too.

I understand the desire to "kit" the carb, but as long as everything works well, the ONLY thing you might gain is to know how everything is. No significant improvement in how things run, usually, as I recall. And . . . it might be worse afterward as what ever was making it work decently well got disturbed, fwiw.

Enjoy!

CBODY67