D Cluley

Active Member

When I got this car 20 years ago, it needed a new top. The main part overhead was in fairly decent shape, but the sail panels were tearing at the bottom, and the rear window was mostly gone. I don't remember what it cost to have it replaced, but I think it was around $800. I got a solid 15 years out of that top, so can't really complain, but the last few years it has been going downhill quickly. Again, as the vinyl shrunk, the sail panels started to tear, and in 2020 the base of the rear window cracked. I mostly drive it with the top down, but it did need a little stabilization, to keep things in place & reasonably water tight. A vinyl from the fabric store and some extra fasteners looked terrible, but made a decent short-term fix.

After redoing the seats in 2020, I started to consider that the top might be something I could do myself. The two shops I knew of years ago have closed, and while I'm sure there's somebody else local, I'm assuming at this point it would be well over $1000. At that point, I could buy all the supplies needed, completely screw up, and get a second try for less than having it done. So, I ordered everything last summer, and eventually got it in January. Dealing with the transmission, turned my June project into an August project, but things are finally underway.

Room to work, let the carnage begin.

Got the weatherstrip and retainers off, and only had to attack one rusted screw with the dremel. I'm kind of amazed.

A little rust at this end of the header, but I kind of expected worse. Seem to be missing one screw from the latch, and the pads have lost all of their padding. Fortunately, I ordered new ones.

The trim strip over the rear of the top is supposed to have a screw that goes into the tack strip on the rear bow. Years ago, it was coming loose, and leaking water, so my solution was to drill through and put a T nut on the inside for a machine screw. Since the hole is already there, will put it back this way, but I'm planning to paint the T nuts, while things are apart.

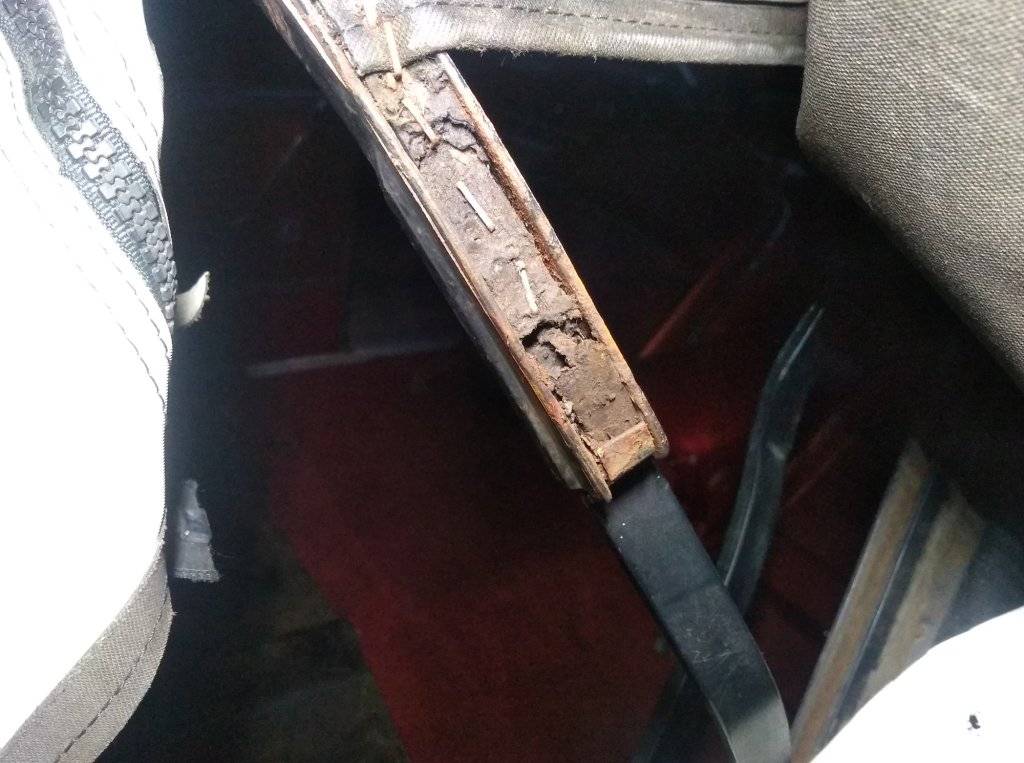

Can't imagine why a screw came loose from this. Definitely going to replace the tack strips.

Main top is completely off, and it's time to call it a night.

After redoing the seats in 2020, I started to consider that the top might be something I could do myself. The two shops I knew of years ago have closed, and while I'm sure there's somebody else local, I'm assuming at this point it would be well over $1000. At that point, I could buy all the supplies needed, completely screw up, and get a second try for less than having it done. So, I ordered everything last summer, and eventually got it in January. Dealing with the transmission, turned my June project into an August project, but things are finally underway.

Room to work, let the carnage begin.

Got the weatherstrip and retainers off, and only had to attack one rusted screw with the dremel. I'm kind of amazed.

A little rust at this end of the header, but I kind of expected worse. Seem to be missing one screw from the latch, and the pads have lost all of their padding. Fortunately, I ordered new ones.

The trim strip over the rear of the top is supposed to have a screw that goes into the tack strip on the rear bow. Years ago, it was coming loose, and leaking water, so my solution was to drill through and put a T nut on the inside for a machine screw. Since the hole is already there, will put it back this way, but I'm planning to paint the T nuts, while things are apart.

Can't imagine why a screw came loose from this. Definitely going to replace the tack strips.

Main top is completely off, and it's time to call it a night.