Wonderwagon

Well-Known Member

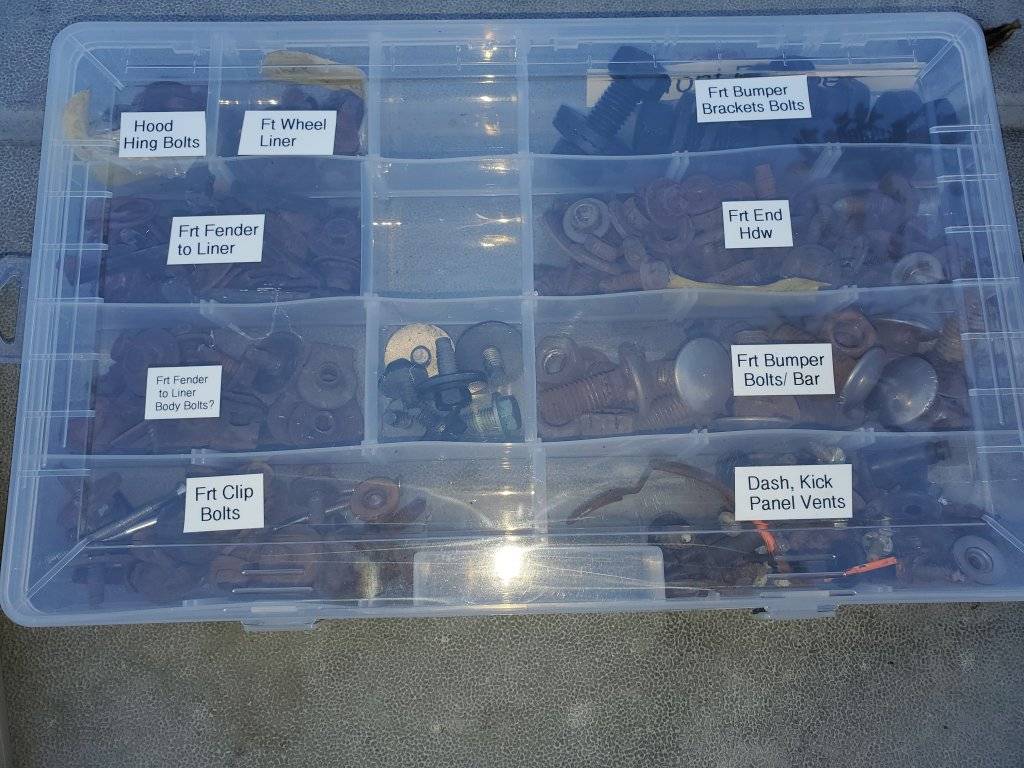

Can not stand chaos, when it comes to parts. Needed to find the hardware for the fenders and liners. Think i found them, now which is which and were do they go. One box down, another to go.

Nice, better than the baggies with masking tape labels I use.Can not stand chaos, when it comes to parts. Needed to find the hardware for the fenders and liners. Think i found them, now which is which and were do they go. One box down, another to go.

View attachment 553168

They where bagged, but when all the parts were retrieved from the shop where the car was. It was a complete mess. Started as finding the hdw for the tailgate door pivot. Got lucky and found it, then the easter egg hunt gor the front fender and wheel housing hardware. Think i found it. Once this all sorted, problem is there was an immense amount in bags labeled Misc Hardware, a$$holes.Nice, better than the baggies with masking tape labels I use.

Hopefully the spray outs and the color applied will match. Not to belittle a point. Where the car was they painted it, and gave no record of paint mix. I have one now.That color is stunning when new, right! Very nice!