You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

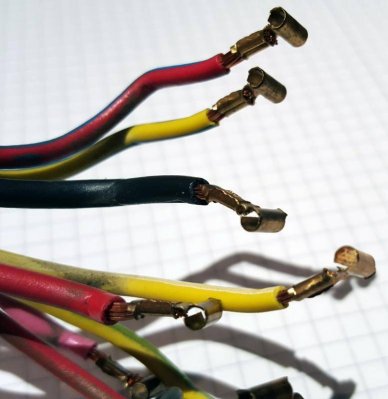

Special wire terminals

- Thread starter vdk2010

- Start date

commando1

Old Man with a Hat

Are they the same size as sparkplug wire terminals?

Nothing in pic to reference to.

Nothing in pic to reference to.

live4theking

Old Man with a Hat

- Joined

- Nov 24, 2014

- Messages

- 12,687

- Reaction score

- 8,890

Normally when the terminal turns the connection 90° it is called a "flag" terminal. I did a couple of quick searches for "Flag Terminal Female Bullet", but came up empty handed.

What is the gauge of this wire? I'll check with a friend that works in the electrical industries.

What is the gauge of this wire? I'll check with a friend that works in the electrical industries.

300rag

It's Not Going to Shift Itself

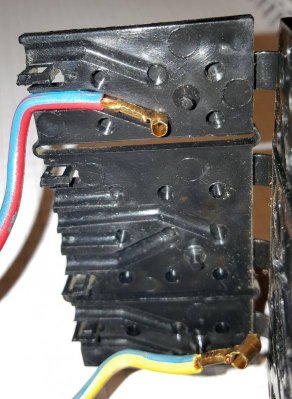

Those look like they are for the power window switch.

Normally when the terminal turns the connection 90° it is called a "flag" terminal. I did a couple of quick searches for "Flag Terminal Female Bullet", but came up empty handed.

What is the gauge of this wire? I'll check with a friend that works in the electrical industries.

Thanks! It's 11 and 13 gauge I think.

The new ones should fit 2,5mm² and 4mm² cables.

commando1

Old Man with a Hat

My gawd. You're even rebuilding the original power seat connectors....:yourock:

http://www.digikey.com/product-sear...onnectors/1442843/page/7?k=terminal connector

http://www.digikey.com/product-sear...onnectors/1442843/page/7?k=terminal connector

live4theking

Old Man with a Hat

- Joined

- Nov 24, 2014

- Messages

- 12,687

- Reaction score

- 8,890

I'm told that this guy could be a source too, but I've not had a chance to check his website out very well.

[FONT="]http://www.oldmoparts.com/[/FONT]

[FONT="]http://www.oldmoparts.com/[/FONT]

My gawd. You're even rebuilding the original power seat connectors....:yourock:

http://www.digikey.com/product-sear...onnectors/1442843/page/7?k=terminal connector

View attachment 66102

Thanks Stan! It's the right direction, but they are too small. 20-24 awg is to small and the barrel is half the size I need them to needs to be.

And yes, I'm replacing every single wire in my imperial!

I'm told that this guy could be a source too, but I've not had a chance to check his website out very well.

[FONT=&]http://www.oldmoparts.com/[/FONT]

Thanks, the webside is not very helpful, but I've send him a mail.

We will see if he can help me.

I believe they are the same as the power window terminals.

commando1

Old Man with a Hat

Did you search the entire list?Thanks Stan! It's the right direction, but they are too small. 20-24 awg is to small and the barrel is half the size I need them to needs to be.

And yes, I'm replacing every single wire in my imperial!

That was only to get you into the right direction.

If AMP, doesn't make it, it doesn't exist,

Did you search the entire list?

That was only to get you into the right direction.

If AMP, doesn't make it, it doesn't exist,

Yes, I did, unfortunately, they are all for 20-24 awg or even 24-26 (according to the description)

I was fnoff at work again... you only beat me by an hour Stan... my goodness you are efficient.

I'm told that this guy could be a source too, but I've not had a chance to check his website out very well.

[FONT=&]http://www.oldmoparts.com/[/FONT]

Andy Bernbaum only dealt with FL and older cars to my knowledge... never hurts to try though.

Thanks Stan! It's the right direction, but they are too small. 20-24 awg is to small and the barrel is half the size I need them to needs to be.

And yes, I'm replacing every single wire in my imperial!

Very ambitious... and should eliminate lots of gremlins. If your not worried about perfect originality I would recommend fusing more circuits, unloading old switches with relays and using conduit or abrasion resistant tape to help prevent future potential for fire.

Did you search the entire list?

That was only to get you into the right direction.

If AMP, doesn't make it, it doesn't exist,

I'm not going to say doesn't exist, but it was the best source I found. Between "flags" and "90 degree" I saw something close to 10 options, including different bullet sizes and wire gauges. You may want to do a thorough recheck and realize finding the exact terminal might not happen. As an alternative, you could try de-crimping some old terminals and add a drop of solder after re-crimping to assure good contact and strength.

Unless someone finds a source that has NOS pieces or a more modern usage... I would be surprised if these exact same terminals are available. Aside from Chrysler's markings, do you see any other manufacture's markings... maybe there was a contractor/supplier who still exists. Good luck to you.

Very ambitious... and should eliminate lots of gremlins. If your not worried about perfect originality I would recommend fusing more circuits, unloading old switches with relays and using conduit or abrasion resistant tape to help prevent future potential for fire.

I'm using heat-resistant wire braid and 3m electrical tape on the entire wiring harness. I'm also replacing all connectors, that are not unique shaped to a specific part, with WeahterPack connectors. For wires I'm using FLRy and FLR automitive wires, but have troubles finding all fancy colors, Chrysler used.

I guess that's the best I could do ;)

I'm not going to say doesn't exist, but it was the best source I found. Between "flags" and "90 degree" I saw something close to 10 options, including different bullet sizes and wire gauges. You may want to do a thorough recheck and realize finding the exact terminal might not happen. As an alternative, you could try de-crimping some old terminals and add a drop of solder after re-crimping to assure good contact and strength.

Unless someone finds a source that has NOS pieces or a more modern usage... I would be surprised if these exact same terminals are available. Aside from Chrysler's markings, do you see any other manufacture's markings... maybe there was a contractor/supplier who still exists. Good luck to you.

That's the last solution, yes. I did that before on the typical flat mopar terminals and will do it again if I have to, even if I prefer clean, new terminals.

I'm using heat-resistant wire braid and 3m electrical tape on the entire wiring harness. I'm also replacing all connectors, that are not unique shaped to a specific part, with WeahterPack connectors. For wires I'm using FLRy and FLR automitive wires, but have troubles finding all fancy colors, Chrysler used.

I guess that's the best I could do ;)

Don't worry about exact matches so much... its nice, but not as important as starting a binder with factory wiring schematics copied and over drawn with updates. Thanks to the computer you could make quite a nice new schematic if your so inclined. I have found that years (days) later, I forget exactly what I did. The possibility of a future owner makes this binder the "bible" for that car... I keep receipts, notes on modifications and part numbers I changed or had trouble finding, etc. Nothing worse than trying to reverse engineer your own changes.

With your changes, which I like... Please consider relays to take load off of switches like your headlights. Headlight switches occasionally burn down cars even when parked. I have personally seen several cars have fires from this including 2 I saw personally. 1 I saved, the other was a poor little girl who locked her car and ran... decided against the liability of breaking her glass, so I called the fire dept. instead.

PVC electrical tape isn't abrasion resistant, careful what type you use.Consider adding a fuse, fusible link or circuit breaker to circuits as close to the battery or fuse panel as you can. Add on fuse box or inline fuses in a relatively convenient location are a wise addition. If you ever blow a fuse, good chance it saved you from damage.

Good luck to you, and any pictures or technical details could help others...

Jeff

Thanks for all your advices!

An update will be posted in my restomod thread as usual when it's enought to show! (http://www.forcbodiesonly.com/mopar-forum/showthread.php?9935-1969-Imperial-progress-thread/page168)

I will ask several questions about adding stuff, tuning oem systems etc. when I'm ready to start building the wiring harness! There are much improvements to make to the original wiring I guess!

About the tape, I don't use much of it, mostly for bundling cables before wrapping them in braid. When using tape for bigger sections, I'm using a factory like cloth tape!

An update will be posted in my restomod thread as usual when it's enought to show! (http://www.forcbodiesonly.com/mopar-forum/showthread.php?9935-1969-Imperial-progress-thread/page168)

I will ask several questions about adding stuff, tuning oem systems etc. when I'm ready to start building the wiring harness! There are much improvements to make to the original wiring I guess!

About the tape, I don't use much of it, mostly for bundling cables before wrapping them in braid. When using tape for bigger sections, I'm using a factory like cloth tape!

MrMoparCHP

Old Man with a Hat

What I have done is cases where I needed a special terminal was to cut the old terminal off then lay the new wire in the crimped groove and solider it in place. I have also done this to piggyback a wire in an existing terminal. I had attempted to unroll the crimp so I could solider the wire in the correct location but that proved to be futile, that is when I just but the wire on the terminal and soldiered it.

Alan

Alan

What I have done is cases where I needed a special terminal was to cut the old terminal off then lay the new wire in the crimped groove and solider it in place. I have also done this to piggyback a wire in an existing terminal. I had attempted to unroll the crimp so I could solider the wire in the correct location but that proved to be futile, that is when I just but the wire on the terminal and soldiered it.

Alan

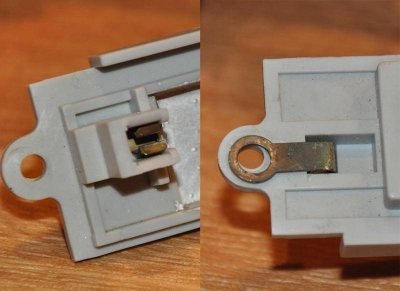

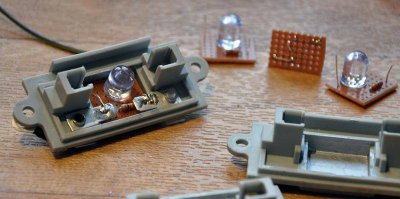

I did the same on a few other parts as well, when they were not replaceable, like on the fender mounted turn signals.

But I experienced corosion problems inside some old terminals that caused in no continuity at all. Like on the instrument cluster illumination.

These terminals are a two piece part, slided together. And you can't part them without breaking them.

That's why I made my own LED boards to replace the original sockets and bulbs.

Buuut, long story short. I will open up the old terminals and solder the new cables in place if I can't find new terminals.

I contacted http://www.oldmoparts.com/ and he guided me to Rhode Island Wire (www.riwire.com) and told me "they will have any connector your need".

We will see.

I used Rhode Island Wire's cloth covered wire for my 53 Windsor project. Really nice stuff.

Similar threads

- Replies

- 10

- Views

- 540

- Replies

- 8

- Views

- 420