The only way I can realistically see to use the other methods outlined above is for the transmission to be out of the car. I can't imagine trying to drill a small hole with no room to even see anything going on clearly enough to not mess a lot of expensive things up. To each his own I guess........................

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TF 727 "How To" shift lever seal replacement

- Thread starter MBar

- Start date

Whiskytango

Member

I wouldnt discount the other methods so quickly. I give squirrel credit . He obviously came up with a solution and it worked. That is the great thing about this forum. Different ideas that work. And the question was how to change the seal. Obviously the best method is when pan and valve body is off. Never tried that tool so can’t comment on it. I have used the modified screw driver many times and it does work. Is it the best way….probably not but it costs nothing to make or try. Like you said, to each their own

I wouldnt discount the other methods so quickly. I give squirrel credit . He obviously came up with a solution and it worked. That is the great thing about this forum. Different ideas that work. And the question was how to change the seal. Obviously the best method is when pan and valve body is off. Never tried that tool so can’t comment on it. I have used the modified screw driver many times and it does work. Is it the best way….probably not but it costs nothing to make or try. Like you said, to each their own

I was really just wondering how you are able to see what you are doing with any precision when the transmission is in the car using that punch tool that was improvised given there is hardly any room between the seal and the floorpan? You would have to be a contorsionist and then some (if Squirrell had the car on a lift and used a mirror then that might well work OK but with the car just on jack stands, it isn't easy to do that way). I also do not believe taking the pan off is easiest - why go through all that mess when in just a few minutes you can change the seal quickly and then drive the car rather than clean up all the mess from draining the oil and then making sure the pan gasket surface of the pan is straight and then hope that it will not leak when you are all done?

If you, however, are just talking about changing the seal when the trans is out of the car, then sure the other methods will likely work fine.

Usually when the selector shaft seal starts to leak there isn't anything else wrong with the transmission so I certainly am not going to take the trans out of the car to change the seal.

Same thing goes with the input shaft seal on the power steering gears. A very similar tool works up there too without having to take the steering box out of the car but you do have to remove the steering colunm or at least pull it back some. To get the tool to grab there too you will need to leverage the tool with a flat, not too long bar up against something nearby in the engine compartment to get enough force on tool threads to turn it into the seal to extricate it from the steering box.

Last edited:

Dan Scully

Well-Known Member

I hdon't need to change the filter and change the ATF, so I found a generic tool sold by NAPA & Etc. Will this work? It is relatively cheap $8.99. Thank you!

https://www.napaonline.com/en/p/BK_...exitBh19fgBNEAQYAiABEgKrM_D_BwE&gclsrc=aw.ds&

Yes, that one should indeed work. Mine is getting pretty worn, so I might pick up one myself.

If you are going to get a new seal, then just to be sure it is the right size, you should order the seal in advance along with the tool so that you can compare the seal size with the tool size to make sure they are compatible.

The tool otherwise looks exactly like the one I use

As stated chk the size . that looks like the one for GM you need the larger one for Mopar

RJ Squirrell

Member

Yes your absolutely right I used an inspection mirror with a long flex handle, position it where you can see what your doing then let go of it and use both hands. I do have a lift though, best present I ever bought myself, I cant get up and down onto a creeper board anymore. Its that getting back up part that my back seems to dislike.

In the 70's my biggest problem with creeper boards was running over my hair-

In the 70's my biggest problem with creeper boards was running over my hair-

You are correct. NAPA only sells the GM-sized seal remover. I can't find anyone that sells the Mopar sized tool at a reasonable price. Looks like there is one seller. A cool $69.95 on Amazon.As stated chk the size . that looks like the one for GM you need the larger one for Mopar

View attachment 482342

3175375

Old Man with a Hat

SST-1031-A

Streetside Tools SST-1031-A - Chrysler - Shift Selector Shaft Seal Remover Installer Transmission Tool

less than Ebaye

Streetside Tools SST-1031-A - Chrysler - Shift Selector Shaft Seal Remover Installer Transmission Tool

less than Ebaye

1970FuryConv

Old Man with a Hat

1973 Dodge Monaco.

I took the Big John approach today, mostly because I would rarely use the $60 tool and I wanted to try a fiber pan gasket.

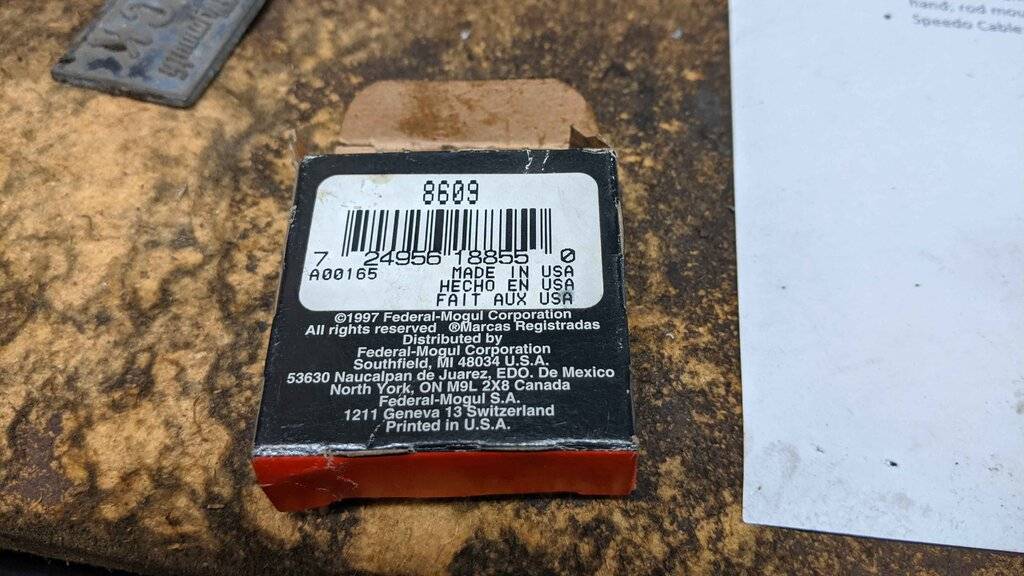

Shift Shaft Seal, National 8609

· Recess or indent for seal mount: finish cleaning with rags, small flat blade screwdriver, pick

· National Seal 8609, Federal Mogul, made in USA: Dynatex transmission grease, lubricate seal and pack between seal and metal housing. Also lubricate recess.

National on right

· Seal tool: bolt 3/8 thread 1.75 inch length, upper washer 1.375 inch diameter, lower washer 1.5 inch diameter, nut 5/8 inch. 9/16 inch wrench on bolt head, 5/8 inch long socket, 3 inch extension, 3/8 ratchet on nut. Scratched fry pans make good trays

· Process: place seal in recess. Assure upper washer is centered on top of seal. Hold bolt head still with 9/16 inch wrench, while tightening nut to firm resistance. Top of seal is flush with housing of transmission.

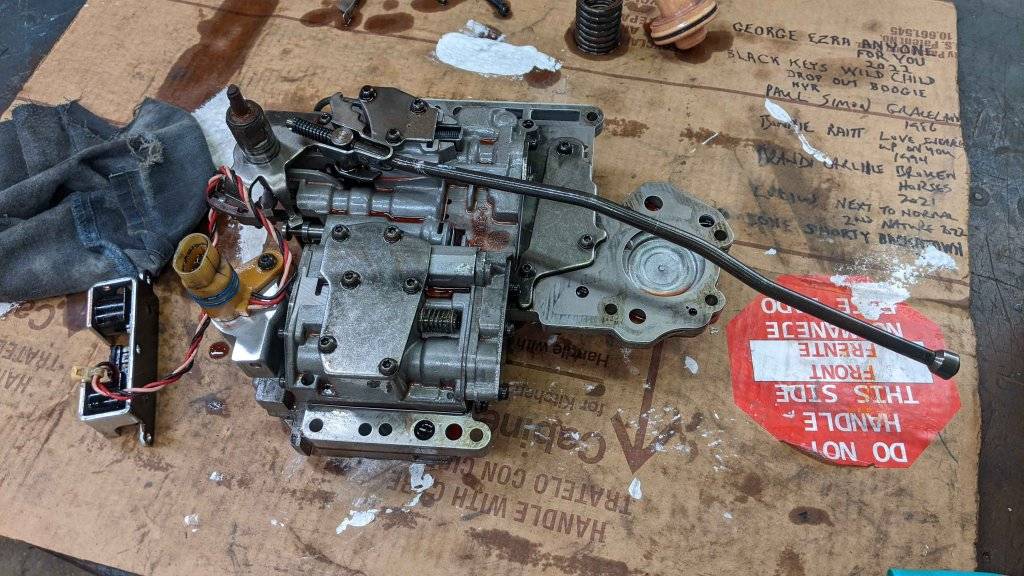

Valve Body

· Valve Body Install: Dynatex onshift shaft. Push shaft through the seal, while assuring that accumulator spring stays upright and also assuring that park rod goes into park rod seat. If the transmission was on the bench, I’d turn output shaft until parking rod seats, but because it is in the vehicle, turning the driveshaft back and forth is required for it to fully seat. It seats on the curved lip visible in the picture and the metal block above the lip has to go up for it to fully seat. Install valve body: 10 bolts, 100”lbs, 7/16 ss, 6ext, adapter, 3/8 torque wrench. To test if you have the park rod fully seated, if you can get your hand on the rod, it should not go forward without starting to lift up although it does have a little play to the rear. Also with the shift lever in the park position, all the way to the rear, and an assistant holding one tire, trying to turn the opposite tire. It should not turn the driveshaft. If you have the car in neutral, for instance, the same test will turn the driveshaft.

Ball at end of park rod seats here

Park rod after valve body installed. Very hard to see whether seated correctly

Valve body. 40 miles on filter so I reused it.

I took the Big John approach today, mostly because I would rarely use the $60 tool and I wanted to try a fiber pan gasket.

Shift Shaft Seal, National 8609

· Recess or indent for seal mount: finish cleaning with rags, small flat blade screwdriver, pick

· National Seal 8609, Federal Mogul, made in USA: Dynatex transmission grease, lubricate seal and pack between seal and metal housing. Also lubricate recess.

National on right

· Seal tool: bolt 3/8 thread 1.75 inch length, upper washer 1.375 inch diameter, lower washer 1.5 inch diameter, nut 5/8 inch. 9/16 inch wrench on bolt head, 5/8 inch long socket, 3 inch extension, 3/8 ratchet on nut. Scratched fry pans make good trays

· Process: place seal in recess. Assure upper washer is centered on top of seal. Hold bolt head still with 9/16 inch wrench, while tightening nut to firm resistance. Top of seal is flush with housing of transmission.

Valve Body

· Valve Body Install: Dynatex onshift shaft. Push shaft through the seal, while assuring that accumulator spring stays upright and also assuring that park rod goes into park rod seat. If the transmission was on the bench, I’d turn output shaft until parking rod seats, but because it is in the vehicle, turning the driveshaft back and forth is required for it to fully seat. It seats on the curved lip visible in the picture and the metal block above the lip has to go up for it to fully seat. Install valve body: 10 bolts, 100”lbs, 7/16 ss, 6ext, adapter, 3/8 torque wrench. To test if you have the park rod fully seated, if you can get your hand on the rod, it should not go forward without starting to lift up although it does have a little play to the rear. Also with the shift lever in the park position, all the way to the rear, and an assistant holding one tire, trying to turn the opposite tire. It should not turn the driveshaft. If you have the car in neutral, for instance, the same test will turn the driveshaft.

Ball at end of park rod seats here

Park rod after valve body installed. Very hard to see whether seated correctly

Valve body. 40 miles on filter so I reused it.

1970FuryConv

Old Man with a Hat

Continued

Shift shaft, Dynatex coated

Shift shaft and seal

727 Transmission Linkage

· Shift Lever: short side of U-shaped mount faces up. Bolt head forward, assure a square nut in contact with indent on shift lever, 7/16 inch short socket, 6 inch extension, ¼ inch ratchet. I installed the lever so it was just above the transmission housing surface.

· Kickdown Lever: short side of U-shaped mount faces up. Bolt head faces rear. Assure square nut in contact with indent on lever, 7/16 inch short socket, 6 inch extension, ¼ inch ratchet. I installed the lever so it was just above the shift shaft.

· Kickdown linkage rod: L-shaped clip. Install with circular opening above and below kickdown lever. Install linkage rod end, lubed with Dynatex, through the clip and lever. Rotate clip until opposite end of clip is firmly engaged around rod.

· Shift Linkage: shift linkage rod to trans shift lever. Flat side of rod goes to shift lever. Rod mounts from top through end of shift lever. Lube with Dynatex and install with the ribbed clip. Repeat process at opposite end of rod where it engages the shift linkage.

So there's my version. Thanks John and Steve for the tips.

Shift shaft, Dynatex coated

Shift shaft and seal

727 Transmission Linkage

· Shift Lever: short side of U-shaped mount faces up. Bolt head forward, assure a square nut in contact with indent on shift lever, 7/16 inch short socket, 6 inch extension, ¼ inch ratchet. I installed the lever so it was just above the transmission housing surface.

· Kickdown Lever: short side of U-shaped mount faces up. Bolt head faces rear. Assure square nut in contact with indent on lever, 7/16 inch short socket, 6 inch extension, ¼ inch ratchet. I installed the lever so it was just above the shift shaft.

· Kickdown linkage rod: L-shaped clip. Install with circular opening above and below kickdown lever. Install linkage rod end, lubed with Dynatex, through the clip and lever. Rotate clip until opposite end of clip is firmly engaged around rod.

· Shift Linkage: shift linkage rod to trans shift lever. Flat side of rod goes to shift lever. Rod mounts from top through end of shift lever. Lube with Dynatex and install with the ribbed clip. Repeat process at opposite end of rod where it engages the shift linkage.

So there's my version. Thanks John and Steve for the tips.

I guess if you have to perform some kind of maintenance on the transmission that requires the fluid be drained and the valve body removed, then your approach is OK. However, I rarely have any other problem with these transmission that would cause me to go through all that. It is no challenge to remove and reinstall the selector shaft seal with the valve body removed.

The same is true when our steering box input shaft seals wear out - I sure don't want to take a part of the steering box apart just to replace that seal either and nothing else is wrong especially with the unit still in the car.

In other words, I am not sure what problem your efforts is solving rather than causing much more of a problem than the issue requires?

I rebuild all of my automatic transmissions myself and aim to use the best parts and take no shortcuts in the process. These transmissions are very rugged and reliable but those input shaft seals are a weak spot where debris can accumulate on top of the seal and can affect their longevity and so will time related deterioration of the seal itself long before anything else requires attention.

Since I do have a lot of cars, I use the special tool frequently and it saves me a a large amount of time collectively.

The same is true when our steering box input shaft seals wear out - I sure don't want to take a part of the steering box apart just to replace that seal either and nothing else is wrong especially with the unit still in the car.

In other words, I am not sure what problem your efforts is solving rather than causing much more of a problem than the issue requires?

I rebuild all of my automatic transmissions myself and aim to use the best parts and take no shortcuts in the process. These transmissions are very rugged and reliable but those input shaft seals are a weak spot where debris can accumulate on top of the seal and can affect their longevity and so will time related deterioration of the seal itself long before anything else requires attention.

Since I do have a lot of cars, I use the special tool frequently and it saves me a a large amount of time collectively.

Last edited:

1970FuryConv

Old Man with a Hat

Our situations are just different. I don't rebuild many of these transmissions or change shift shaft seals often. I have 4 c-bodies, 3 of which are on the road. Further, I had changed the filter and used a rubber pan gasket. While the NAPA rubber gasket doesn't seem to leak on my wife's Nitro, it did leak on my 1973 727, possibly because of differences in pan depth. (727 Surfaces were clean and dry and pan bolts tightened at 150-150"lbs.) I ordered a new fiber pan gasket and a new seal and dropped the valve body in process of replacing both. Hope the fiber pan gasket works better.I guess if you have to perform some kind of maintenance on the transmission that requires the fluid be drained and the valve body removed, then your approach is OK. However, I rarely have any other problem with these transmission that would cause me to go through all that. It is no challenge to remove and reinstall the selector shaft seal with the valve body removed.

The same is true when our steering box input shaft seals wear out - I sure don't want to take a part of the steering box apart just to replace that seal either and nothing else is wrong especially with the unit still in the car.

In other words, I am not sure what problem your efforts is solving rather than causing much more of a problem than the issue requires?

I rebuild all of my automatic transmissions myself and aim to use the best parts and take no shortcuts in the process. These transmissions are very rugged and reliable but those input shaft seals are a weak spot where debris can accumulate on top of the seal and can affect their longevity and so will time related deterioration of the seal itself long before anything else requires attention.

Since I do have a lot of cars, I use the special tool frequently and it saves me a a large amount of time collectively.

If I had to service as many c-bodies as you do, I would get the seal remover tool. I am grateful for the tip about the National Seal 8609. Made in USA was a big unexpected plus. Thanks!

1970FuryConv

Old Man with a Hat

The shift shaft seal is done on my 1970 Fury. The only other vehicle I needed to do one on was my 1990 Dodge W150 pickup. I put 1994 46RH overdrive transmission in it. Really the only difference is that the valve body has an overdrive switch that is wired to lock up and overdrive solenoid's. I have not done a valve body on the later 46 RE, 8 pin connector. Does anyone know if it's basically the same? Just curious. I don't have a truck that new.

I should have left the overdrive lockup solenoid attached to the valve body. I didn't understand that the switch came down with the valve body. All I really needed to do was unplug the switch. I reinstalled the valve body and installed the solenoid assembly at 35 inch pounds, because the torx screws look exactly the same as those for the filter except that they're not as long.

I should have left the overdrive lockup solenoid attached to the valve body. I didn't understand that the switch came down with the valve body. All I really needed to do was unplug the switch. I reinstalled the valve body and installed the solenoid assembly at 35 inch pounds, because the torx screws look exactly the same as those for the filter except that they're not as long.

Philip Andrews

Well-Known Member

Does anybody have a p/n for the smaller seal that fits inside the shifter pin, to seal the kickdown arm? Both the shifter arm and kickdown arm are leaking on mine; I've got the pan off, gonna drop the valve body and pop the seal out with the arm removed for better access.

Thanks

Phil

Thanks

Phil

glennb49

Active Member

Now I have to work up the courage and do mine Thanks for the great how to!

Since no one answered in the past 10 months...Does anybody have a p/n for the smaller seal that fits inside the shifter pin, to seal the kickdown arm? Both the shifter arm and kickdown arm are leaking on mine; I've got the pan off, gonna drop the valve body and pop the seal out with the arm removed for better access.

Thanks

Phil

Part # 2466548

This is the same seal used in the case for the throttle shaft in 1965 727 and 904 trans along with some newer (2000+) applications. It may also be used in earlier (than 1965) applications, but I've never verified that. In fact, I have one on order right now for my '65.

3175375

Old Man with a Hat

I finally got to attempting to replace the shift shaft seals and I am going to have to drop the valve body. Not enough clearance to use the tool on the 68 Fury II with a 318 and a 904.

I might as well put in a Transgo shift kit in while I’m at it…

I might as well put in a Transgo shift kit in while I’m at it…

65-Newport

New Member

Hey guys,

Do you think this leak is from the shift shaft seal?

Do you think this leak is from the shift shaft seal?

If you mean the seal on the throttle linkage (sometimes called "kickdown"), it's possible, but it's a different, smaller seal than what we've discussed here.

More likely, it's coming from the shifter cable.

But, if it is the throttle linkage seal, here's what I posted earlier if it helps.

Part # 2466548

This is the same seal used in the case for the throttle shaft in 1965 727 and 904 trans along with some newer (2000+) applications. It may also be used in earlier (than 1965) applications, but I've never verified that. In fact, I have one on order right now for my '65.

65-Newport

New Member

Got it. Thanks Big John!If you mean the seal on the throttle linkage (sometimes called "kickdown"), it's possible, but it's a different, smaller seal than what we've discussed here.

More likely, it's coming from the shifter cable.

But, if it is the throttle linkage seal, here's what I posted earlier if it helps.

3175375

Old Man with a Hat

There’s two seals in the throttle linkage interface.

Similar threads

- Replies

- 3

- Views

- 223

- Replies

- 5

- Views

- 1K

- Replies

- 29

- Views

- 5K

- Replies

- 0

- Views

- 695