Vodka, I just spent the last, nearly, 2 hours reading your thread... WOW. This is a big thread for a big car.

Anyway. VERY impressive work. you re getting this yacht set straight.

Thanks!

Vodka, I just spent the last, nearly, 2 hours reading your thread... WOW. This is a big thread for a big car.

Anyway. VERY impressive work. you re getting this yacht set straight.

I'd guess that if the amperage of the transformer is too low to fire the motor the fuse or circuit breaker of the transformer would pop. If that doesn't happen amperage is probably not the problem.

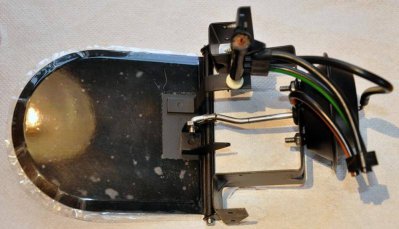

Operating the motor without load won't strip the gears but what the FSM says (I know I read it somewhere, too) about not operating without the load of the headlight doors sounds plausible, i. e. the gear and cam might be too quick and overturn the stop wedges which in turn operate the contacts.

When I cleaned my motor, I bench testet it with the cover open, so I could see when the gear/cam was nearing the end of travel and I just disconnected power right before the contacts would open. That was fine with me since I had no doubt the contacts would work, it was the actual motor that had been stuck.

I only had a 12 V battery for that, but you could try dialing in a lower voltage with your DC transformer like, let's say 8 V and try running the motor with that (without load). It would probably run slower and should not be able to overrun the cam/wedge/contacts action.

If it doesn't move at all with 8 V, slowly increase the voltage until the motor budges.

The wedges and contacts are good for two things:

1. allow for the motor to stop even if power ist continued to be fed into the mechanism from the relais;

2. prevent the motor to turn in the wrong direction. If the cam and wedges work properly, only one set of contacts can be closed at the same time, so only one of the two windings (open/close) in the motor is fed.

So all you need is the negative cable from your power source connected to the the motor housing or the brown wire - if it provides good ground internally - and a positive wire going into either one of the two wires going to the contacts (green or yellow wire). If the motor doesn't move, try cnnecting power to the other of the green and yellow cables. It should move then.

Mind you that the green and yellow wires each connect to individual windings in the motor, one is for turning the motor clockwise, the other for turning the motor counter-clockwise.

The brown cable is only to make sure that the motor has good ground. It seems that Chrysler engineers did not trust the motor housing simply being bolted to the fixture, right behind the grille. As can be seen from the diagram the brown cable is connected to the left headlight ground.

The green wire from the headlight switch connects to the headlight door relais and then continues on to the low beam headlight positive connector. This connection to the relais serves as a ground for the relais plunger coil if the headlight is turned off. Current flows through the plunger coil in the relais, through the filament in the headlight, but it has not enough power to produce any light there. If the plunger coil in the relais is so energized, the plunger is pushed agains a contact giving current way to the "close" cable of the motor. If the headlight is turned on, then the green headlight wire has current to feed the headlight, so there is no more current flowing through the plunger coil in the relais and the plunger is drawn against the "open" contacts in the relais by its spring. Then current from the igintion switch is fed to the "open" cable to the headlight motor. This can be seen on these MTSC pages.

I just clicked on this thread because I also love '69 Imperials... The first time I ever recall seeing a coupe was as a kid on a trip to Florida with my parents around 1986. My father exited I-75 for gas/food in Kentucky or Tennessee. Somewhere between the interstate and our stop, I spotted a deep plum Imperial coupe "dumped" in someone's front yard. I'm sure I begged him to stop, but at age 14, probably didn't have much pull and we continued on. It's possible I might even have the car on videotape or film, because I was doing a lot of that from the back of our Dodge minivan.

I don't have a few days to read this entire thread, but it sure would be something if that is the same car I see in the first few photos on page one. Can anybody say where this care came from?

I'll certainly keep it in mind... But do you know if your car came from Tennessee? Maybe even Georgia? They never built many in the first place and even fewer in that color. When I saw those photos, it really looked like the same area which would have been close to US interstate 75.

I have to disappoint you on that. She spend all her life in NY.

What products do you use to refinish your parts? they look nearly NOS

I am sure I am not the only one who would like a tutorial of what it is you do to make your parts look so amazing.There are many steps... If you have questions about specific materials, just ask