Cartel

Active Member

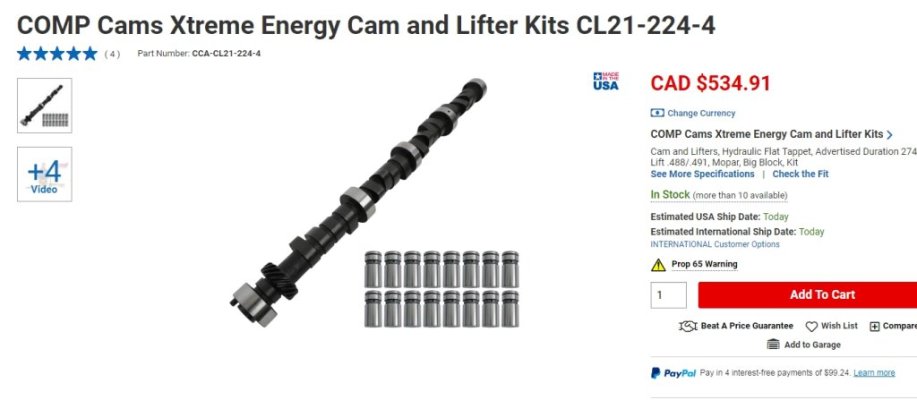

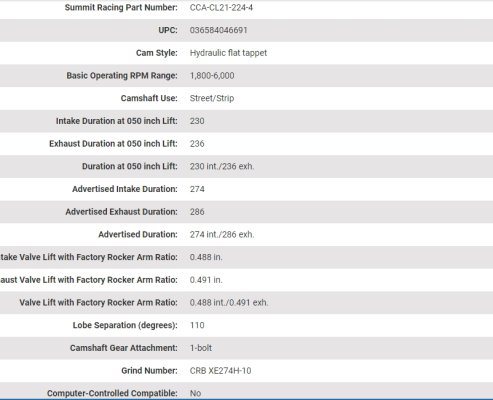

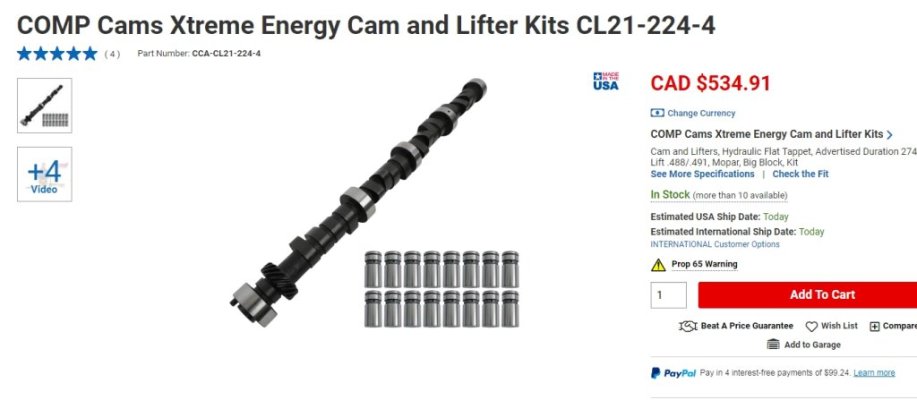

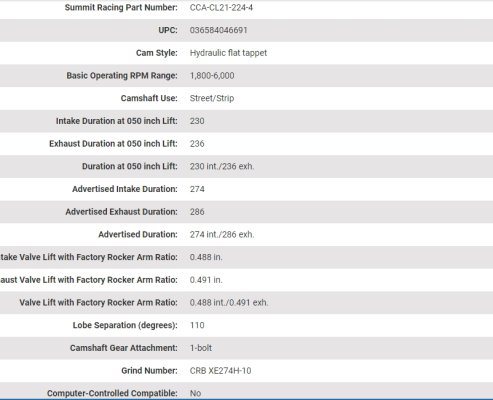

I was thinking of using this cam CL21-224-4 with the stealth heads.

I dont want to have interference problems with the L2315 flat top pistons.

The shop said I'll be ok but I need to verify everything.

Comp says 68 and up because different lifters. I read here if I go with the matching push rods I'll be ok. Is that 100%?

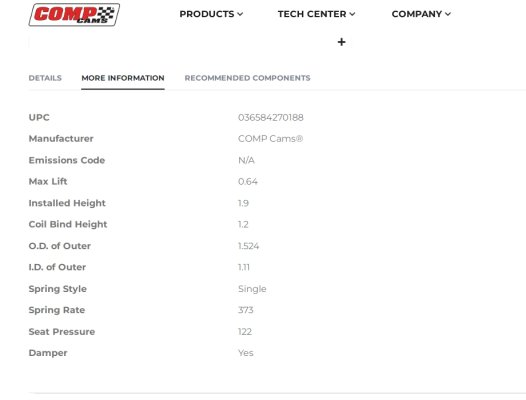

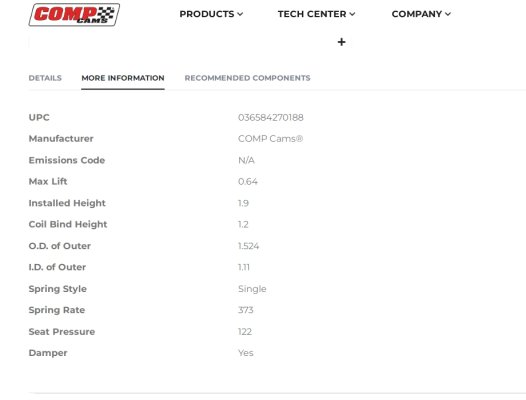

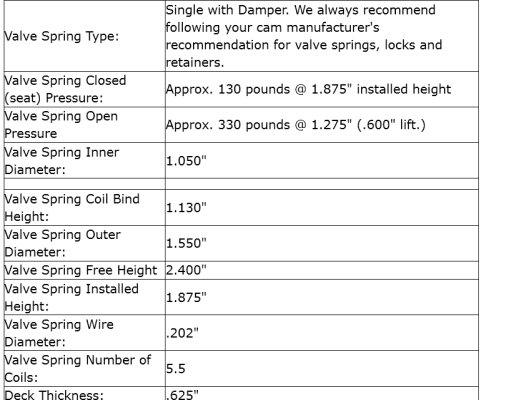

Comp suggests these springs for the cam: COMP Cams Valve Springs 911-16

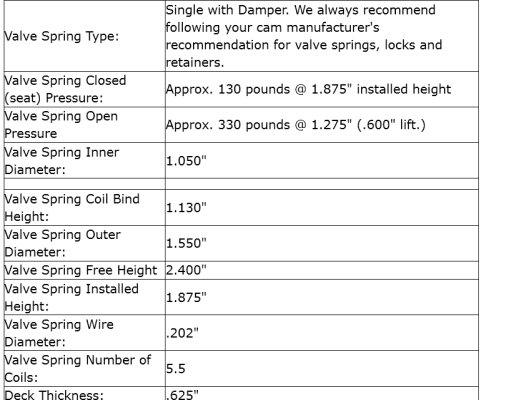

Stealth list their spring pretty close:

Anyone care to help me choose I'm starting to get a bit overwhelmed.

I dont want to have interference problems with the L2315 flat top pistons.

The shop said I'll be ok but I need to verify everything.

Comp says 68 and up because different lifters. I read here if I go with the matching push rods I'll be ok. Is that 100%?

Comp suggests these springs for the cam: COMP Cams Valve Springs 911-16

Stealth list their spring pretty close:

Anyone care to help me choose I'm starting to get a bit overwhelmed.