commando1

Old Man with a Hat

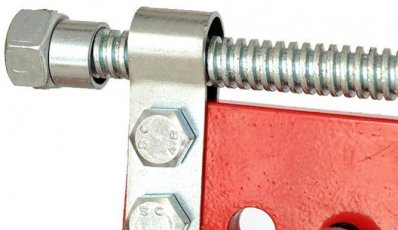

Yes, all the handle does is give you blisters and bloody your knuckles. Like Jer, I welded a humongous nut to replace the crank and zip that leveler back and forth with a pneumatic ratchet.I've not seen it mentioned here but once now but I'm assuming you guyz all pull the hood like I do? One thing I did with my leveler that I'd suggest that any body should do that haz one or is thinking of getting one is the S**T CAN that crank handle and weld BOTH NUTZ ON BOTH ENDZ of that threaded rod and use your impact gun with the appropriate size impact socket and alwayz point the short protruding end toward the fire wall. You have no idea how fast you can tilt the engine WITH the trans using the impact. You only have to use it like that once to know you've done the right thing, Jer

I was wondering about that. The handle does look kind of flimsy and with 750+ lbs hanging on the end it can't be easy to turn.

After removing the hood and laying a sheet of plywood against the radiator, I can remove and install the engine with the tranny attached but only using the leveler to steeply angle the drive train down and in. To me the leveler was priceless.

Oh!!! And dropping the tranny cross member was required. Another AMHIK item.

Posted via Topify on Android