Hey all,

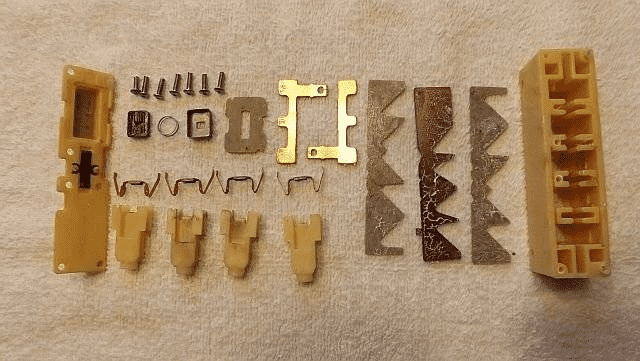

With these 4 and 5 button vacuum controllers for heat/defrost/ac, it's my understanding from the articles I've read that there are plates that slide back and forth to allow vacuum to be applied to certain pathways within the system. Picture of a non-AC vacuum switch disassembled. Sliding plates are on the right.

From what I've gathered, the plates are lubricated with a Lubriplate style lithium grease, and of course, over the many years these things have been around, if not used they get sluggish or bound up as the lubricant hardens.

My question(s) is(are) this(these):

If everything else checks out with the switch (vacuum ports are in good shape, electrical connections are good etc.), is there a way to soften the lubricant that is already there rather than going to the risk of attempting to open the unit up? Opening the device involves drilling out or cutting the plastic bonding studs, and we've all read the "oops!" stories.

Can I spray into the ports a solvent that will work? Would it creep along and soften things up, especially if the plates already move, albeit sluggishly? Could I draw the solvent along with a vacuum pump?

Thanks in advance!

With these 4 and 5 button vacuum controllers for heat/defrost/ac, it's my understanding from the articles I've read that there are plates that slide back and forth to allow vacuum to be applied to certain pathways within the system. Picture of a non-AC vacuum switch disassembled. Sliding plates are on the right.

From what I've gathered, the plates are lubricated with a Lubriplate style lithium grease, and of course, over the many years these things have been around, if not used they get sluggish or bound up as the lubricant hardens.

My question(s) is(are) this(these):

If everything else checks out with the switch (vacuum ports are in good shape, electrical connections are good etc.), is there a way to soften the lubricant that is already there rather than going to the risk of attempting to open the unit up? Opening the device involves drilling out or cutting the plastic bonding studs, and we've all read the "oops!" stories.

Can I spray into the ports a solvent that will work? Would it creep along and soften things up, especially if the plates already move, albeit sluggishly? Could I draw the solvent along with a vacuum pump?

Thanks in advance!