Gentlemen, I need a little help please....

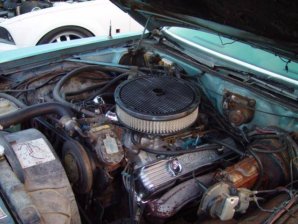

I have a 440 in my 73 Town&Country with an uneven idle and I've run out of ideas as to what it may be.

Engine fires up cold or hot on first turn of the key with proper starting procedure (one pump and hold part open when cold and hold open part way when warm). Engine is smooth off idle with a little gas and at slightly higher rpm higher rpm (too high for idle).

Current uneven idle occurs when warm or cold. Engine holds uneven idle at 650 to 700 rpm. Idle is irregular in its unevenness as in not a regular miss.

Car has about 63000 miles.

Here's what I've done so far.....

First, it is in proper tune with new correct plugs and nos Mopar suppression wires.

All vacuum hoses are correctly routed and I checked them all for leaks. OSCA valve is working and not leaking as is vacuum advance, EGR, thermal valves on block and radiator.

Checked the brake booster... No leaks.

New nos ballast... No change.

Timing is checked and within spec at 8.5 degrees BTC.

I rebuilt the thermoquad. No problems found.

Any ideas? What should I check.

Thanks.

I have a 440 in my 73 Town&Country with an uneven idle and I've run out of ideas as to what it may be.

Engine fires up cold or hot on first turn of the key with proper starting procedure (one pump and hold part open when cold and hold open part way when warm). Engine is smooth off idle with a little gas and at slightly higher rpm higher rpm (too high for idle).

Current uneven idle occurs when warm or cold. Engine holds uneven idle at 650 to 700 rpm. Idle is irregular in its unevenness as in not a regular miss.

Car has about 63000 miles.

Here's what I've done so far.....

First, it is in proper tune with new correct plugs and nos Mopar suppression wires.

All vacuum hoses are correctly routed and I checked them all for leaks. OSCA valve is working and not leaking as is vacuum advance, EGR, thermal valves on block and radiator.

Checked the brake booster... No leaks.

New nos ballast... No change.

Timing is checked and within spec at 8.5 degrees BTC.

I rebuilt the thermoquad. No problems found.

Any ideas? What should I check.

Thanks.

Last edited: