Update: alright, much like the block's heater hose inlets and outlets, I finally got off my lazy *** and decided to get around to doing this...and it actually went quite well, albeit with a few hiccups. It's still a work in progress, but right now, I can confirm that even with the stock air filter (3.5 inch), it juuuust clears the hood and that's with a 1/2 inch phenolic spacer too! You'll need the following parts however:

- phenolic spacer (apparently these carbs suffer from heat soak and these spacers reportedly help a lot with this)

- if the spacer doesn't come with a stud kit, get a 2 inch stud kit

- 350 mm/14 inch air cleaner base plate, recessed is not necessary

- 280 mm/11 inch ID Air filter, either 3.5 inch or 2.75 inch. Fram CA127 or CA305 respectively for cross referencing. Not sure if the lower flow rate of the 2.75 inch will be noticeable.

- Air cleaner cover stud of at least 6 inches when using a 2.75 inch filter, else go 6.75-7 inches with the 3.5 inch filter. The stud that came with the AVS2 was 5.5 inches and just a bit too short.

- fuel hose or steel fuel line to connect the fuel filter to the carby.

Again,

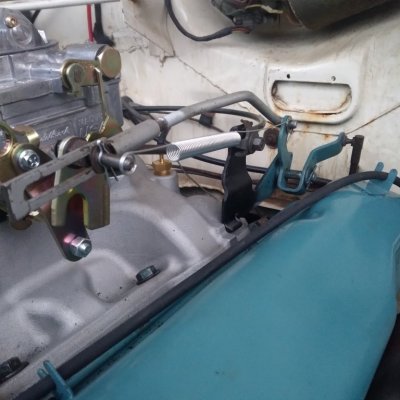

this is still a work in progress, so there may be other parts you may or may not need; I haven't gotten around to testing out the throttle cable and kickdown linkages with the brackets yet.

This square bore, 4-hole spacer I found was from a local shop for a VERY reasonable price compared to what Edelbrock and other retailers are asking. Just 20 AUD, fortunately for me, he was in the same city as me so I just went and picked it up, saving the shipping fee. The stud kit it came with was a bit short, overall length is 45mm; you might be able to get away by partially threading the intake side threads, but I didn't feel too sure about that so I'm going to get a

2 inch overall length stud kit from Rocket Industries, it's only $9.60. The 45mm stud kit was just shy under the top surface of the spacer, you'd need at a bare minimum of a 50mm to thread nuts on it...which just so happens to be the 2 inch kit.

As for the air cleaner base, for those who wish to use the stock air filters, I took a gamble, and it paid off:

Aeroflow AF2851-1400 - fairly cheap, the stock filter fits perfectly on this base plate. The great thing is it also has a 5/8" hole on the inner side of the filter if you want to hook up a PCV hose to the oil/breather cap. This can also be bought from Rocket Industries. Using the factory pie tin with this, there is now about an inch-wide gap all around the circumference between the base and the cover, but it's really only visible if you look down the air horn, or from underneath. The main concern is ensuring an airtight seal between the cover and the base, which this setup still definitely does.

The air cleaner cover stud that came with the AVS2 was 5.5 inches - fully threaded into the carby, it was too short when used in conjunction with the 3.5 inch filter. With the 2.75 inch filter, only partially threading the stud will give just enough thread to tighten the wingnut down, there's still plenty of engagement in the carby, but if it still irks you, get a 1/4-20 threaded rod and cut it to 170 mm or 6.75 inches. This will enable usage of both 3.5 and 2.75 inch tall filters.

Now I don't know about the genuine Weiand 8008 intakes, but this knockoff...well, you get what you pay for. While I got mine for half the price (a result of helping out the seller with his own cars and some computer/tech support stuff) of a real 8008 from a local retailer, the casting isn't completely perfect - the kickdown pivot point bracket that you can see in Cartel's image...it didn't fit on this intake. The casting is too wide, so I'll have to grind off a decent chunk to get it to fit. The throttle return spring bracket I also had to grind a bit as the casting was too big on that side too. I suspect that the OG 8008 intakes won't suffer from these problems and you probably won't have to go through this.

For us RHD people, there's enough slack in the throttle cable to not require modifying it, but the clamp itself may sit rather short so you might need to stick it in a vise or use pliers and bend it.

Another problem I encountered was the 3/8" vacuum port on the intake that has a little auxiliary 1/8" barb coming out of it, this sucker is absolutely stuck on the old intake, I'm just going to buy one 1/8" barb-3/8" NPT fitting, and one 3/8" barb-1/4" NPT fitting in order to take advantage of the vacuum port on the carby, as well as the port on the intake. The 1/8" barb is for the vacuum-operated vent controls. I'm using separate fittings for these because reproductions are insanely expensive.

I got a 5/16 inch coated steel fuel line, and bent it partially following the original fuel line, up to the carby fuel inlet barb. A pipe bending tool will help a lot for this, but isn't absolutely essential, you can do this by hand if you're not bothered by the messy look. The stock carby inlet is 3/8 inch while the line is 5/16, but as others have mentioned previously, you can use a single flare on the line to allow it to accommodate a 3/8 inch fuel hose as needed.

Before:

View attachment 699817

After:

View attachment 699818

@Captainfury thought I'd include you on this since you were also wanting to do a similar conversion.