Tire Whisperer

New Member

Some background history of tire construction is necessary before arbitrarily picking a cold(cold as in, early morning, not yet driven) pressure to inflate the tires in older rides such as the OP's 1968 Polara.

The primary difference in the construction of bias-ply vs radial ply tires is the direction in which those plies - reinforcing belts from inner to outer bead. Bias ran diagonally, overlapping. Radial runs perpendicular between the beads(part of tire that mates with the rim or wheel).

This construction, plus different rubber compositions used back then, meant that bias tires were of generally stiffer construction, particularly the side walls. That is why you see such relatively low cold recommended pressures on the tire & load placards affixed to the door frame, trunk lid, etc of vintage cars. 24-26psi was a typical recommendation, but pressures as low as 15psi(think Corvair!) up to 28psi were not out of the realm back then.

My rule of thumb for converting an old MOPAR, or any other bias-ply era vintage, to modern radials of equivalent OE size, or Coker's look-like radials that mimic the bias shape, is to add between 5-10psi to the OE values on the original vehicle tire placard.

On that Corvair, that would equate 20-25psi cold in front, and 31-36 cold out back. As long as that front-rear offset is observed, the car should handle as well, if not even better, than it did when it left the showroom in 1961 or '66.

Now, some of you might be concerned that the cold pressures specified for bias tires back in 1960-something or the pressures specified for cars with radials more recently, 2010 or 2022 for instance, seem "low". Well, I did also, until a couple years ago...

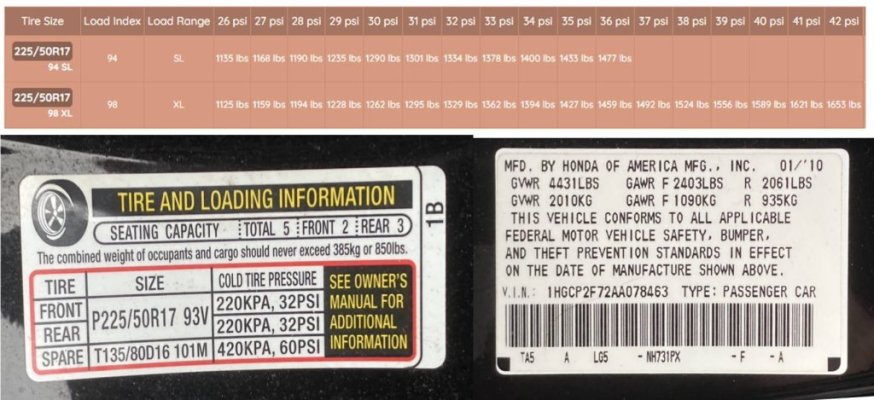

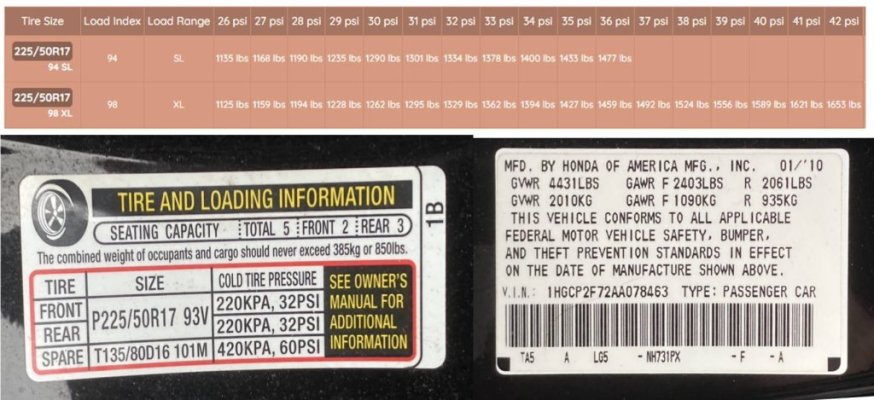

I did something I never did before: I consulted both the Tire & Load, and Certification placards on on my 2010 Accord driver door pillar, and tire load inflation tables on tirepressure dot org. My uploaded image shows all three items consulted. The 'Certification' is the label with gross weights and build date on it.

I took the gross axle weight rating(GAWR) for each axle, and divided it in two - as in - per tire. (remember: 'Gross' = curb weight PLUS five passengers PLUS full tank of gas PLUS full trunk of luggage. ...

PLUS the family dog.)

Basically, the max load plus curb.

Then, I consulted the aforementioned table to see if Honda did their homework when selecting cold tire pressures for that year's Accord.

At 32psi cold, the OEM tire size for my car supports 110.9(111!) percent of front gross axle weight, and 129 percent of rear gross axle. In total, about 139 percent of Gross Veh weight.

A ten percent safety margin per axle is generally considered industry minimum, with 20 percent over, the average.

So in theory, at least, there is no acceptable or rational excuse to exceed the vehicle placard tire pressures at all, on passenger vehicles at least . Aside from higher shipping and storage pressures, to prevent flat spotting or cargo shift in transit. Some car makers, particularly certain German and Italian ones, provide a set of slightly higher cold pressures explicitly for sustained high speed (100-plus mph) operation.

In fact, I could run my rear tires 1-2psi cold lower than in the fronts, and still far exceed gross axle capacity back there.

A while later, I performed the same exercise, using the same sources, for my friend and neighbors 2019 Hyundai Tucson.

At 35psi cold per Hyundai, the OE tire size supports 130 and 135%, respectively, of Front and Rear gross axle weight. At 33psi, those figures dropped by about 10 percent, and the crossover drove more like a car than like a pair of ice skates...!

I think Hyundai was aiming more for fuel economy with that 35 figure, while Honda's pressures were a compromise between economy and handling.

Hopefully all of you now realize that the Max Cold Pressure stamped on tire sidewalls only provides a canvas, of sorts for that tire to be used on a wide range of vehicle sizes and classifications. It has ZERO relevance, whatsoever, for the load and handling requirements of any specific vehicle, from 1940 or so, to present. Regardless of how your car may 'feel' when running your pressures closer to or at Max. And 'personal preference'? I don't even know what that phrase means, lol!

And don't obsess over 'radial bulge' - where the rubber touches the pavement! Think of the caterpillars on an Army tank the next time you see one in the movies or at a parade.

So to summarize: The first order of business when a vehicle manufacturer selects wheels & tires, and cold tire pressures for a new model, or redesign of an existing, is load capacity. As explained several paragraphs back, the current industry norm for passenger cars is 10 to 20 percent over gross axle weight. A 10-20% safety margin. For a fully loaded car mind you.

Leaning toward 10% over gives good handling pressures, and going as high as 30% over is usually done for fuel economy.

The only challenge is to find gross axle/vehicle weight values for older cars, as such labels were not affixed to them as they are today.

I hope this example makes you and other drivers believers.

The primary difference in the construction of bias-ply vs radial ply tires is the direction in which those plies - reinforcing belts from inner to outer bead. Bias ran diagonally, overlapping. Radial runs perpendicular between the beads(part of tire that mates with the rim or wheel).

This construction, plus different rubber compositions used back then, meant that bias tires were of generally stiffer construction, particularly the side walls. That is why you see such relatively low cold recommended pressures on the tire & load placards affixed to the door frame, trunk lid, etc of vintage cars. 24-26psi was a typical recommendation, but pressures as low as 15psi(think Corvair!) up to 28psi were not out of the realm back then.

My rule of thumb for converting an old MOPAR, or any other bias-ply era vintage, to modern radials of equivalent OE size, or Coker's look-like radials that mimic the bias shape, is to add between 5-10psi to the OE values on the original vehicle tire placard.

On that Corvair, that would equate 20-25psi cold in front, and 31-36 cold out back. As long as that front-rear offset is observed, the car should handle as well, if not even better, than it did when it left the showroom in 1961 or '66.

Now, some of you might be concerned that the cold pressures specified for bias tires back in 1960-something or the pressures specified for cars with radials more recently, 2010 or 2022 for instance, seem "low". Well, I did also, until a couple years ago...

I did something I never did before: I consulted both the Tire & Load, and Certification placards on on my 2010 Accord driver door pillar, and tire load inflation tables on tirepressure dot org. My uploaded image shows all three items consulted. The 'Certification' is the label with gross weights and build date on it.

I took the gross axle weight rating(GAWR) for each axle, and divided it in two - as in - per tire. (remember: 'Gross' = curb weight PLUS five passengers PLUS full tank of gas PLUS full trunk of luggage. ...

PLUS the family dog.)

Basically, the max load plus curb.

Then, I consulted the aforementioned table to see if Honda did their homework when selecting cold tire pressures for that year's Accord.

At 32psi cold, the OEM tire size for my car supports 110.9(111!) percent of front gross axle weight, and 129 percent of rear gross axle. In total, about 139 percent of Gross Veh weight.

A ten percent safety margin per axle is generally considered industry minimum, with 20 percent over, the average.

So in theory, at least, there is no acceptable or rational excuse to exceed the vehicle placard tire pressures at all, on passenger vehicles at least . Aside from higher shipping and storage pressures, to prevent flat spotting or cargo shift in transit. Some car makers, particularly certain German and Italian ones, provide a set of slightly higher cold pressures explicitly for sustained high speed (100-plus mph) operation.

In fact, I could run my rear tires 1-2psi cold lower than in the fronts, and still far exceed gross axle capacity back there.

A while later, I performed the same exercise, using the same sources, for my friend and neighbors 2019 Hyundai Tucson.

At 35psi cold per Hyundai, the OE tire size supports 130 and 135%, respectively, of Front and Rear gross axle weight. At 33psi, those figures dropped by about 10 percent, and the crossover drove more like a car than like a pair of ice skates...!

I think Hyundai was aiming more for fuel economy with that 35 figure, while Honda's pressures were a compromise between economy and handling.

Hopefully all of you now realize that the Max Cold Pressure stamped on tire sidewalls only provides a canvas, of sorts for that tire to be used on a wide range of vehicle sizes and classifications. It has ZERO relevance, whatsoever, for the load and handling requirements of any specific vehicle, from 1940 or so, to present. Regardless of how your car may 'feel' when running your pressures closer to or at Max. And 'personal preference'? I don't even know what that phrase means, lol!

And don't obsess over 'radial bulge' - where the rubber touches the pavement! Think of the caterpillars on an Army tank the next time you see one in the movies or at a parade.

So to summarize: The first order of business when a vehicle manufacturer selects wheels & tires, and cold tire pressures for a new model, or redesign of an existing, is load capacity. As explained several paragraphs back, the current industry norm for passenger cars is 10 to 20 percent over gross axle weight. A 10-20% safety margin. For a fully loaded car mind you.

Leaning toward 10% over gives good handling pressures, and going as high as 30% over is usually done for fuel economy.

The only challenge is to find gross axle/vehicle weight values for older cars, as such labels were not affixed to them as they are today.

I hope this example makes you and other drivers believers.

Last edited: