monaco75

Senior Member

Shes not red anymore. Spent a few hour getting the bulk of it off today. Need to pick up another can of cleaner to get the few tiny spots left.

UPS, and Fedex dropped off a few more goodies.

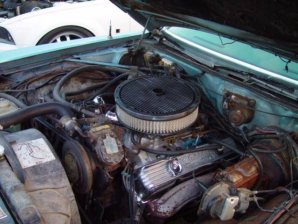

Playing/checking the new valve covers. Its gonna take some RTV to get these to seal up. Seems like a normal problem... They don't flex like the steal covers do, and with the heads not being completely straight, they have a bit of a gap at the ends... I had some new thick rubber gaskets left over from the newport to test with. Still a bit of play.

Not a good pic, but you can kinda see the space...

Has anyone here installed these on their cars? How did you go about popping the hole open for the breather, and pcv valve? I've read of people using a hole saw, and others just a hammer. The alluminum seems pretty thick there, and I don't see any relief cuts around the area.. Don't want to mess up my new covers...

UPS, and Fedex dropped off a few more goodies.

Playing/checking the new valve covers. Its gonna take some RTV to get these to seal up. Seems like a normal problem... They don't flex like the steal covers do, and with the heads not being completely straight, they have a bit of a gap at the ends... I had some new thick rubber gaskets left over from the newport to test with. Still a bit of play.

Not a good pic, but you can kinda see the space...

Has anyone here installed these on their cars? How did you go about popping the hole open for the breather, and pcv valve? I've read of people using a hole saw, and others just a hammer. The alluminum seems pretty thick there, and I don't see any relief cuts around the area.. Don't want to mess up my new covers...